Abstract

Guidelines are proposed for the design of production systems, which are understood to involve both designing and making products. Production system design serves the three goals of production systems: do the job, maximize value, and minimize waste. For each of the latter two, ends-means hierarchies are proposed that progressively answer the question “What should we do to achieve a goal?”, moving from desired ends to actionable means.

Production system design extends from global organization to the design of operations; e.g., from decisions regarding who is to be involved in what roles to decisions regarding how the physical work will be accomplished. Previously, project planning has focused primarily on organizational structuring and creation of work breakdown structures that divide the work to be done. We propose to include the production system itself, which has been virtually invisible and taken for granted. Doing so necessarily involves moving from a conception of production solely in terms of transformation of inputs to a wider concept of production that acknowledges the flow and value generation character of production.

The paper ends with a discussion of further research needs, originating from the ends-means hierarchies developed.

Keywords: Construction, production system, production system design, waste, value, value generation.

Introduction

The first task in any productive endeavor is production system design, which extends from global organization to the design of operations; e.g., from decisions regarding who is to be involved in what roles to decisions regarding how the physical work will be accomplished. Several terms are presently being used to refer to this stage of production. Hayes et al. (1988) define manufacturing architecture as including its hardware, material, and information flows, their coordination, and managerial philosophy. Also Rechtin and Maier (1997) speak of architecting a manufacturing system. In the context of construction, the concept of work structuring has been used to refer to production system design (Ballard, et al., 2001).

Previously, project planning in construction has focused primarily on organizational structuring and creation of work breakdown structures that divide the work to be done. We propose to include the production system itself, which has been virtually invisible and taken for granted. Doing so necessarily involves moving from a conception of production solely in terms of transformation of inputs to the TFV (Task/Flow/Value) concept of production (Koskela 2000). TFV adds conceptions of production as consisting of flows of materials and information through networks of specialists, and the conception of production in terms of the generation of customer value.

Creating the conditions for system control and improvement is included in systems design. However, guidelines and techniques for applying control and making improvements lie beyond design and will be treated in later papers.

The following guide for design of project-based production systems differs from those developed for manufacturing systems5 primarily in the conceptualization of production to include both the designing and making of products. The guidelines here are in the form of ends-means hierarchies that progressively answer the question “What should we do to achieve a goal?”, moving from the desired ends of maximizing value and minimizing waste to actionable means.

Maximizing Value and Minimizing Waste: Universal Goals

In the lean approach, products are designed to provide maximum value to their purchasers and users. On the other hand, production systems are designed to achieve the purposes of both their customers and those who ‘deliver’ the system, the producers. Those purposes may vary greatly, but producers, in their role as ‘guardians’ of the production system, have goals that are appropriate for all such purposes; i.e., maximize value and minimize waste. Of course, it is also vital that producers be clear about their business strategies. Product and customer selection are but two of the critical choices that are driven by business strategy. However, once products and customers are selected, once projects are awarded, the producer must design, control, and improve a temporary production system for delivering those products to those customers. We suggest that designing such systems to maximize value and minimize waste is always the right thing to do.

Maximizing value gives the producer the greatest leverage over pricing. Maximizing value and minimizing waste generates the greatest profit, the difference between price and cost. Consequently, regardless of specific business strategies, profit-seeking producers should strive to maximize value and minimize waste. This also holds true for so-called non-profit organizations.

In what circumstances would it not be in the interest of producers to maximize value or minimize waste? A few come to mind: 1) When producers profit from waste, and 2) When generating value for customers reduces value for producers. For example, producers make money from waste when changes are exploited as a primary source of profit. Inadequate design combined with design-bid-build may leave the construction contractor no alternative but to rely on design errors and omissions to make the contract profitable.

As regards the second circumstance, generating value for customers reduces value for producers when there is a choice between increasing the producer’s profit and investing some of that potential profit in upgrading the product through selection of systems, equipment, or parts. Does the fact that producer and customer interests sometimes conflict in the traditional production system invalidate the claim that value and waste are universal goals? We suggest that the conclusion should rather be to structure production systems to avoid such contradictions, which arise because of the way production systems are structured.

Customer purposes may vary widely, from immediate profit generation to market expansion to ease of operation to wanting to delight your mother with a birthday gift. Generating value for customers is to better enable them to realize their purposes. Minimizing waste in production may reduce the customer’s cost or may increase the producer’s profit. Either way, it is an appropriate goal.

Clearly there can be conflicts between the values of producers and customers, between various customers, or between various producers as we face production system design decisions. Aligning interests is a critical element in production system design, but tradeoffs are unavoidable, just as they are unavoidable in product design when there are multiple customers. The unending pursuit of perfection is in large part driven by the desire to elevate the level of performance at which tradeoffs must be made6.

Even though maximizing value and minimizing waste are universal goals of project-based producers, nonetheless it is vitally important for producers to decide on business objectives and strategies (Porter 1996). One reason for this: as producers get better at designing, operating, and improving (aka, managing) production systems, they often must change the commercial structures in which they work in order to reap those gains. For example, if a producer conceives itself as a service provider and structures contracts to be paid for time provided, the commercial incentive is to spend more time rather than less. As it learns how to do more in less time, this contradiction between commercial objectives and production system capabilities must be resolved. Typically it is resolved by moving from service provider to product provider, or ultimately, to solution provider, as is the case in build-operate situations.

A Third Goal for Production Systems

The TFV framework implies a third production system goal. Along with maximizing value and minimizing waste, the issue is about producing the product, a goal so obvious that it can easily be overlooked. This goal is principally pursued in traditional project design through the development of a work breakdown structure. This ‘WBS’ divides the total work scope into its elements and is typically mated with an organizational breakdown structure, which assigns responsibility for ‘delivery’ of those elements. This guide to production system design is intended to be an alternative to WBS/OBS, appropriate for the TFV (Task/Flow/Value) concept of production as distinct from the task only.

The assumptions behind WBS/OBS are flawed: work scope is not divisible into independent elements. Project elements are typically interdependent. Value is delivered because the whole is more than the sum of the parts; i.e., value emerges from interdependence. That flawed conception is the result of a truncated concept of production. However, the task view is a legitimate part of the TFV concept. We suggest that this is, considered within the TFV concept, the realm of contracts between the producers representing interdependent production systems; contracts being the means for coordinating the actions across multiple systems. In the case of project-based production systems, contracts link the temporary system to the larger complex of production systems that exist independently of the project.

It is inappropriate to conceive contracts exclusively in terms of transactions; i.e., the exchange of commodities. Contracts can also be relational; e.g., keeping a promise, getting married versus buying a loaf of bread. The contracts that stitch together the elements of project production systems are relational. Misconceiving them in terms of transactions promotes enforcing conformance to contractual agreements, regardless of changes in project objectives, and neglecting the interdependence of production system members.

In any case, in this paper, we neglect the third production system goal, which we intend to treat in future papers.

Ends-Means Hierarchies

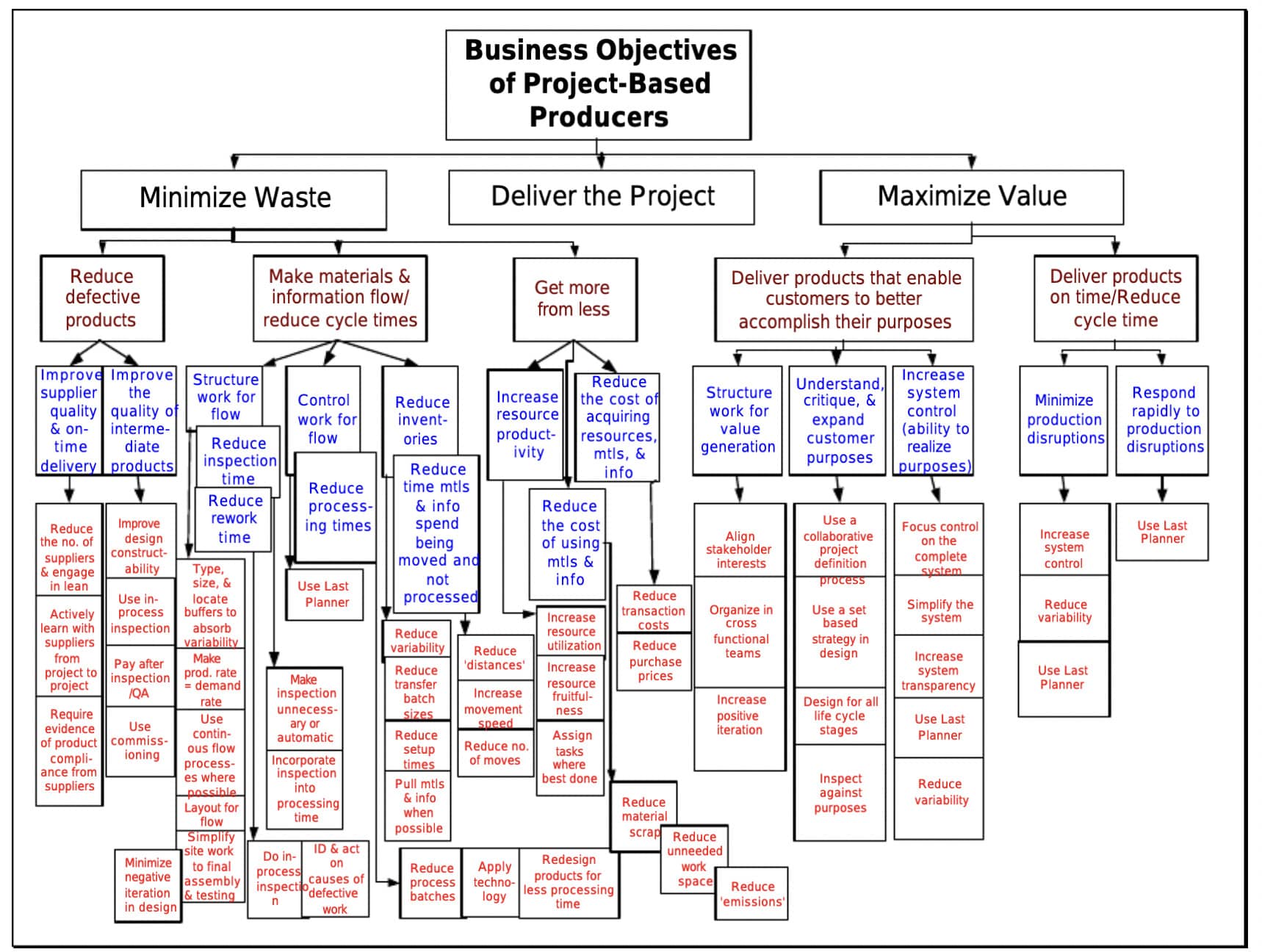

In the following ends-means hierarchies, guidelines are proposed for the design of project-based production systems. Figure 1 provides an overview of the hierarchies. Note that some levels included in the form of outlines below are not included in the figure for lack of space.

For visibility and greater detail, we also present ends-means hierarchies arranged in outline form. Hierarchies for each of the production system goals are presented separately, initially the first three levels, then adding more detailed, actionable levels one at a time.

Maximize Value: Levels 1-3 (Level 1=Maximize Value)

-

Deliver products that enable customers to better accomplish their purposes

-

Structure work for value generation

-

Increase system control (ability to realize purposes)

-

Increase system control (ability to realize purposes)

-

-

Deliver projects on time/Reduce cycle time variation

-

Minimize production disruptions

-

Respond rapidly to production disruptions

-

How maximize value? By delivering products that enable customers to better accomplish their purposes and by delivering those products when they are needed.

How deliver products that…? By structuring work for value generation, by understanding, critiquing, and expanding customer purposes, and by increasing the ability to realize purposes7.

Each of these can in turn be expanded into a hierarchy of means that progressively become less goal-like and more actionable.

Maximize Value: Levels 1-4

-

Deliver products that enable customers to better accomplish their purposes

-

Structure work for value generation

-

Align stakeholder interests

-

Organize in cross functional teams

-

Increase positive iteration

-

-

Understand, critique, & expand customer purposes

-

Use a collaborative project definition process

-

Use a set based strategy in design

-

Design for all life cycle stages

-

Inspect against purposes

-

-

Increase system control (ability to realize purposes)

-

Focus control on the complete system

-

Simplify the system (reduce the number of parts and linkages)

-

Increase system transparency

-

Use Last Planner system of production control8

-

Reduce variability, including latent product defects9

-

-

-

Deliver products on time/Reduce cycle time variation

-

Minimize production disruptions

-

Increase system control

-

Reduce variability

-

-

Respond rapidly to production disruptions

-

Use the Last Planner system of production control

-

-

For example, how might we “understand, critique, and expand customer purposes”? By using a collaborative project definition process, by using a set based strategy in design, by designing for all life cycle stages (and the customers of our product in each of those stages), and by inspecting/evaluating prospective or actual system outputs against customer purposes.

A similar ends-means hierarchy can be generated for the goal of minimizing waste, of which there are four basic types: defective products, lack of flow, lost capacity, and avoidable cost; here expressed in three categories.

Minimize Waste: Levels 1-3

-

Reduce defective products

-

Improve supplier quality and on-time delivery

-

Improve the quality of intermediate products within the production process, either design or construction

-

-

Make materials and information flow/reduce cycle times (i.e., minimize time mtls or info spend being inspected, reworked, waiting in queues, being processed, or moving)

-

Structure work for flow

-

Control work for flow

-

Reduce inventories (time spent waiting in queues)

-

Reduce inspection time

-

Reduce processing times

-

Reduce rework time

-

Reduce time materials and information spend being moved and not processed

-

-

Get more from less

-

Increase resource productivity, aka realized capacity (but subordinate to value, defect minimization, & flow)

-

Reduce the cost of acquiring resources, materials, and information

-

Reduce the cost of using materials and information10

-

Defects may linger hidden in products after they are delivered to customers. Such defects are categorized under the value heading in this analysis because they reduce the value provided customers. Defects within the production process may be attacked within the suppliers’ production systems or within the project production system.

Flow11 is a fundamental concept indicating the production system’s striving for instant delivery. As such, it incorporates both continuity (not stopping) and speed. The coordination of multiple flows is important in all production systems, but especially in project-based production systems like construction because of the complexity of products and the number of suppliers. Coordination of flows obviously reduces delays and rework, but is largely achieved through planning and control. Consequently coordination of multiple flows (increase system control) is considered on the value side of the hierarchy.

Resources are things that have limited capacity to bear loads; e.g., labor, tools, equipment, space, and time. Resource management can be divided between acquisition and use. Getting the most out of resources once they have been acquired has traditionally been pursued under the rubric of ‘productivity improvement’. Minimizing the cost of acquiring those resources also reduces waste, but is subordinate to productivity improvement because of the latter’s impact on production system performance12.

It may be useful to note that the above hierarchy applies equally well to both designing and making. For example, improving the quality and on-time delivery of design ‘products’ from external suppliers is certainly appropriate. As is increasing the flow of information in design by reducing batch sizes, reducing rework, etc.

Minimize Waste: Levels 1-4

-

Reduce defective products

-

Improve supplier quality and on-time delivery

-

Reduce the number of suppliers and engage them in pursuit of the lean ideal

-

Actively learn with suppliers from project to project

-

Require evidence of product compliance from suppliers

-

-

Improve the quality of intermediate products

-

Improve design constructability

-

Use in-process inspection

-

Pay after inspection/quality assurance

-

Use commissioning processes13 to demonstrate system and facility functionality and capacity

-

-

-

Make materials and information flow/reduce cycle times (i.e., minimize time mtls or info spend being inspected, reworked, waiting in queues, being processed, or moving)

-

Structure work for flow

-

type, size, & locate buffers to absorb variability & match the value of time vs cost for this customer

-

Make throughput=demand rate (avoid overproduction [waste] and underproduction [loss of value])

-

Structure work in continuous flow processes when feasible

-

Layout for flow

-

Simplify site installation to final assembly and commissioning

-

Minimize negative iteration in design

-

-

Control work for flow

-

Use the Last Planner system of production control

-

-

Reduce inventories (time spent waiting in queues)

-

Reduce variability (a primary reason for inventories)

-

Reduce transfer batch sizes (get stuff out of queues asap)

-

Reduce setup times (a ‘cost’ that constrains inventory reduction)

-

Pull matls & information through the production system14

-

-

Reduce inspection time

-

Make inspection unnecessary or automatic; aka, pokayoke

-

Incorporate inspection in processing time

-

-

Reduce processing times

-

Reduce process batches

-

Redesign products to require less processing time

-

Apply technology that reduces processing time

-

-

Reduce rework time

-

Do in-process inspection

-

Identify and act on causes of defective work

-

-

Reduce time materials and information spend being moved and not processed

-

Reduce ‘distances’ over which materials and information are to be moved

-

Increase movement speed

-

Reduce the number of moves; e.g., strive for ‘one touch’ material handling on site

-

-

-

Get more from less

-

Increase resource productivity, aka realized capacity (but subordinate to value & flow)

-

Increase resource utilization

-

Increase resource fruitfulness

-

Assign tasks where they can best be done; e.g., shift detailed eng. to suppliers

-

-

Reduce the cost of acquiring resources, materials, and information

-

Reduce transaction costs

-

Reduce purchase prices

-

-

Reduce the cost of using materials and information

-

Reduce material scrap

-

Reduce unneeded work space

-

Reduce ‘emissions’

-

-

Minimize Waste: All Levels

-

Reduce defective products

-

Improve supplier quality and on-time delivery

-

Reduce the number of suppliers and engage them in pursuit of the lean ideal

-

Actively learn with suppliers from project to project

-

Require evidence of product compliance from suppliers

-

-

Improve the quality of intermediate products

-

Improve design constructability

-

Use in-process inspection

-

Pay after inspection/quality assurance/p>

-

Use commissioning processes to demonstrate system and facility functionality and capacity

-

-

-

Make materials and information flow/reduce cycle times (i.e., minimize time mtls or info spend being inspected, reworked, waiting in queues, being processed, or moving)

-

Structure work for flow

-

type, size, & locate buffers to absorb variability & match the value of time vs cost for this customer

-

Make throughput=demand rate (avoid overproduction [waste] and underproduction [loss of value])

-

Match bottleneck capacity to demand rate

-

Pull materials and information through the production system

-

-

Structure work in continuous flow processes when feasible

-

Balance processing times of the production units

-

Use multiskilled workers to smooth work flow between production units

-

-

Layout for flow

-

Simplify site installation to final assembly and commissioning

-

Minimize negative iteration in design

-

Use the Design Structure Matrix (DSM) to eliminate avoidable iteration

-

Use strategies for reducing negative iteration at team assignment level

-

Accelerate iteration through team session

-

Design to the upper end of interval estimates; e.g., loads

-

Shift overdesign where estimates can best be made or overdesign can be done at least cost

-

-

-

-

Control work for flow

-

Use the Last Planner system of production control

-

Try to make only assignments with the following quality characteristics: definition, soundness, sequence, size, learning

-

Measure plan reliability

-

Identify and act on root causes of plan failure

-

Explode scheduled tasks as they enter the project lookahead window (typically 3-12 weeks)

-

Analyze lookahead tasks for constraints and act to remove those constraints

-

Allow lookahead tasks to maintain their scheduled dates only if they can be made ready in time

-

Balance load and capacity by retarding/advancing scheduled tasks and/or reducing/increasing resources

-

-

-

Reduce inspection time

-

Make inspection unnecessary or automatic; aka, pokayoke

-

Incorporate inspection in processing time

-

-

Reduce inventories (time spent waiting in queues)

-

Reduce variability (a primary reason for inventories)

-

Underload resources15

-

Identify & act on causes of variability

-

-

Reduce transfer batch sizes (get stuff out of queues asap)

-

Reduce setup times (a ‘cost’ that constrains inventory reduction)

-

Pull matls & information through the production system

-

-

Reduce processing times

-

Reduce process batches

-

Redesign products to require less processing time

-

Apply technology that reduces processing time

-

-

-

Reduce rework time

-

Do in-process inspection

-

Identify and act on causes of defective work

-

-

Reduce time materials and information spend moving

-

Reduce ‘distances’ over which materials and information are to be moved

-

Increase movement speed

-

Reduce the number of moves; e.g., strive for ‘one touch’ material handling on site

-

-

-

Get more from less

-

Increase resource productivity, aka realized capacity (but subordinate to value & flow)

-

Increase resource utilization

-

Match load & capacity (apply enough load to utilize available capacity)

-

Reduce system variability (allows greater utilization for a given throughput rate)

-

-

Increase resource fruitfulness

-

Develop skills

-

Improve design for fabrication and installation

-

Assign tasks where they can best be done; e.g., shift detailed engineering to suppliers

-

-

-

Reduce the cost of acquiring resources, materials, and information

-

Reduce transaction costs

-

Reduce purchase prices

-

-

Reduce the cost of using materials and information

-

Reduce material scrap

-

Reduce unneeded work space

-

Reduce ‘emissions’

-

-

-

-

Application of the Design Guide

Priorities

The relative priority of goals at the same level in a hierarchy is in one sense dependent on customer and producer value. For example, reducing project duration beyond some preagreed magnitude may not be valuable to a specific client in specific circumstances. However, there also seems to be a more general sense of relative priority of same-level goals, which has to do more with system capability, as distinct from specific choices how to utilize that capability. For example, we contend that value generation has priority over waste reduction. In other words, when faced with a choice between generating value and reducing waste, choose value generation. The very meaning of value supports this position. In our terms, value is what enables recipients to better accomplish their purposes. Consequently, its determination and delivery would seem to have priority over reducing the waste in that delivery. ‘It doesn’t matter what the product costs, if it’s not what the customer wants.’ Moving from value generation to waste reduction is also typically the temporal order of design, implementation, and improvement.

On the other hand, if the product is what the customer wants, then what it costs, and waste generally, can become very important. Waste may make the product prohibitively expensive; i.e., despite its value, the customer either cannot afford to pay for it or system waste delays its delivery beyond the point that the product is needed by the customer. When that occurs, the best way to generate value may be to reduce waste. Clearly the priority of value generation over waste reduction is not a simple matter of choosing between alternative actions, as is perhaps clear from the number of instances in which the same means are listed for both ends.

Within waste reduction, we propose that ‘reducing product defects’ is prior to ‘reducing cycle time’, which in turn is prior to ‘getting more from less’. The reason lies in the impact of each of these ‘factors’ on the superordinate goals of maximizing value and minimizing waste.

A caution about resource productivity: In the construction industry, there has been a tendency to optimize resource productivity locally to the detriment of system performance. As stated previously, within the lean framework, resource productivity improvement is subordinate to the goals of value generation and waste reduction. The first task is to achieve a certain level of flow (speed) and defect performance (quality), including the location of capacity buffers as needed to absorb variability without sacrificing cycle time, should minimizing delivery time be valuable. Then, a follow-on task is to reduce the resources needed to maintain or improve that level of flow and defect performance. In no case should flow or defect rate be allowed to worsen in order to improve resource utilization or productivity. This entire issue of relative priorities is clearly an area for further development.

Metrics

Measurements at lower levels may be useful, but the primary measures of production system performance16 are at Level 2:

Deliver products that enable customers to better accomplish their purposes: customer surveys and post-occupancy evaluations

Deliver products on time: on-time delivery rates

Make materials and information flow: process flow analysis and project durations (cycle times)

Get more from less: productivity measurements, costs, scrap rates, etc.

Reduce defective products and process: % product defects discovered at various process stages and % process defects such as safety and health incidents.

Designing a Project-based Production System

Now that we have a hierarchy of ends and means, how might it be used in production system design—especially of project-based production systems?

One use is to answer specific questions of technique; e.g., 'How do we go about reducing inventories?'. Another use is as a guide to making investment decisions; e.g., 'Which is more important on this project, keeping the client’s cost within his budget or accelerating project completion?' Further, like all checklists, the hierarchy can serve as a reminder lest something vital be overlooked. For example, has sufficient consideration been given to minimizing environmental impacts from operation of the facility? Moreover, on the basis of the hierarchy, a strategy map17 for developing a company's production system can be prepared. Lastly, the hierarchy can be used as a template for construction of system models for simulating alternative designs.

Needed Research

Given the above ends-means hierarchies, what do they reveal about needed research? Are there ends for which means need to be developed, tested, or improved? Actually, almost every item in the hierarchy could be - and many already are being - further developed. Here we suggest the following more fundamental areas where research is needed:

What are the principles for selecting the push or pull production control method in a particular situation?

Does the transformation view (i.e. getting the job done) need a hierarchy of its own now that related issues have been interpreted from the point of view of waste?

Do we need separate hierarchies for design and production (due to differences in context and terminology, hierarchies tailored to each stage might be more user-friendly)?

What are the guidelines for carrying out post-occupancy evaluations and feeding the results back to the production system?

How should we interpret transparency in a construction project context?

What are the guidelines for increasing positive iteration and reducing negative iteration in design?

What are the guidelines for mixed push/pull work flow control systems?

Conclusions

Production system design has been neglected. In this paper, guidelines have been proposed for the design of project-based production systems, of which construction is one type. In comparison to prior research, these guidelines provide the following novel features:

The Toyota Production System is not the starting point. TPS is not a model to be imitated or adapted. The starting points are rather Koskela’s Task/Flow/Value theory of production systems and the selection of project-based production systems as the domain.

The production system is understood to involve both designing and making products.

The guidelines are derived from first principles and are thus theory-based, in contrast to heuristic principles presented in prior research.

The guidelines acknowledge three different conceptualizations of operations, whilst prior research has generally been based on one conceptualization.

Work structuring is conceptualized as production system design.

Maximizing value and minimizing waste are put forward as universal goals for producers, regardless of their specific business objectives and strategies.

Value generation is conceived in terms of producer as well as customer purposes.

Flow is conceptualized as the progression of intermediate products (materials or information) through the production system, as opposed to the traditional lean production/manufacturing conceptualization of flow as all temporal states of materials other than processing; i.e., as non-value-adding states of materials.

Flow is conceptualized as the system’s innate striving for instantaneous delivery and hence minimization of cycle time.

Control is understood as a means for generating greater value, as opposed to being understood only as a means for reducing waste, or only as a means for delivering contractual commitments.

Waste is categorized in terms of defective products, lack of flow, lost capacity, and avoidable cost.

The category is proposed: Get More From Less.

Footnotes

Glenn Ballard: Research Director, Lean Construction Institute, 4536 Fieldbrook Road, Oakland, CA 94619. 510/530-8656, ballard@leanconstruction.org, and Associate Adjunct Professor, Construction Eng. & Mgmt. Program, Dept. of Civil & Env. Eng., University of California at Berkeley

Lauri Koskela: Senior Researcher, VTT Building Technology, Concurrent Engineering, P.O.Box 1801, FIN-02044 VTT, Finland, Phone +358 9 4564556, Fax +358 9 4566251, E-mail lauri.koskela@vtt.fi

Gregory Howell: Executive Director, Lean Construction Institute, Box 1003, Ketchum, ID 83340. 208/726-9989, howell@leanconstruction.org

Todd Zabelle: President, Strategic Project Solutions and member, Board of Directors, Lean Construction Institute. 415/533-8494, tzabelle@strategicprojectsolutions.net

For a current approach to the design of manufacturing systems (i.e., ‘making’ only), see http://psd.mit.edu/.

An example: The level at which time-cost tradeoffs are made is determined by the degree of variability in the system, which can be represented by PPC (percent plan complete). Higher PPC (lower variability) allows greater resource utilization at a given pace of production, or a faster production rate at a given level of resource utilization, thus ‘elevating’ the level at which the time-cost tradeoff is made.

Project control is usually conceived with the purpose of minimizing negative variance from planned cost and schedule, typically within a contract management perspective, but sometimes dedicated to reducing waste. We suggest that the purpose of control is not only to reduce waste, but more actively, to cause a desired rate and sequence of work to be done so those various work flows are coordinated. It is the coordination of work flows that reduces waste and also increases the ability to realize purposes; i.e., generate value.

Details of the Last Planner system are shown in the outline for Waste Reduction following. Also see “Shielding Production” at www.leanconstruction.org.

Variability can be either of product or process, both understood as variation from an expected or desired state. Some variation is a result of how products and processes are designed and controlled. Some is natural and unavoidable, but only quantifiable within the context of management action. Consequently, the pursuit of perfection progressively minimizes variation, approaching ever more closely its natural limits.

An example: “Critical Success Factors” adopted by Malling Products in the U.K. are defined as 100% Reliability, Lead Time Towards Zero, Six Sigma Quality, Zero Safety Incidents & Suggestions for Improvement by Team Members. All are in support of the ideals outlined in this paper. None address traditional measurements such as cost, ROI, etc.

Note that flow as defined here refers to an ideal phenomenon (of flow); in current technical and everyday usage, flow most often refers to an empirically observable phenomenon that usually is imperfect in comparison to the ideal.

See the discussion under Priorities in the section on Application of the Design Guide.

Commissioning is a set of formal procedures for assuring that what is delivered to customers meets their needs. It typically includes some means for assessing the adequacy of design, conformance of products to the design (including testing and integration of subsystems into functional facility systems), and preparation of the customer for assuming custody and control, as in operator training. It may also include some type of post occupancy evaluation. Commissioning has long been done in industrial facilities, especially those involving continuous flow processes (pharmaceuticals, petroleum, etc.), but is now becoming popular in commercial building, especially as buildings go more high-tech. For more information, see the website of the Building Commissioning Association: http://www.bcxa.org/.

Pull is not a universal means, but rather requires satisfaction of the condition that lead times fall within the window of reliability; i.e., the time in advance that future states of the production system can be accurately forecast. Given the long lead times for many components and services, together with the small windows of reliability now characteristic of the construction industry, push mechanisms will inevitably be needed for some time to come, and perhaps always in some degree. The structuring of pull/push mechanisms is a much needed area for research.

Strictly speaking, underloading is a means for reacting to or accommodating variability at the work station where it is implemented, but also reduces work flow variability at downstream work stations.

Schonberger (1996) stresses the importance of measuring first-order results, like defect rates, in comparison to second-order results, like productivity, and bottom-line results, like profit. The metrics suggested deal primarily with such first-order results.

Kaplan and Norton (2000) describe the use of such strategy maps in the wider context of company strategy.

References

Ballard, G., Koskela, L., Howell, G., and Zabelle, T. (2001). “Production System Design: Work Structuring Revisited.” LCI White Paper 11, January 24, 2001. 14 p.

Hayes, R.H., Wheelwright, S.C. & Clark, K.B. (1988) Dynamic Manufacturing, Creating the Learning Organization. Free Press, New York.

Kaplan, Robert S. & Norton, David P. (2000) Having Trouble with Your Strategy? Then Map It. Harvard Business Review, September-October, pp. 167-175.

Koskela, Lauri (2000). An exploration towards a production theory and its application to construction. Espoo, VTT Building Technology. 296 p. VTT Publications; 408. Read here

Porter, Michael (1996) What Is Strategy? Harvard Business Review, November-December, pp. 61-78.

Rechtin, Eberhardt & Maier, Mark W. (1997) The Art of Systems Architecting. CRC Press, Baton Rouge.

Schonberger, Richard J. (1996) World Class Manufacturing: The Next Decade. The Free Press, New York. 275 p.