Abstract

Implementing lean means an organization (project or enterprise) transforms itself from a current state to a future state vision that incorporates a lean ideal. This paper proposes a strategy for organizations to increase the likelihood of success when going through a lean transformation. This approach considers construction projects as the basis for transformation, and proposes a narrow and deep implementation approach for the transformation effort.

The paper highlights key elements for a successful implementation including vision, skills, incentives, resources, and detailed action plans. It reinforces the need for heavy-weight project leadership to control behavioral development during the transformation and presents a series of concepts and techniques that support a better understanding of human and team behavior.

The paper concludes with a series of recommendations for organizations that envision a transformation event towards lean project delivery.

Keywords: Behavioral development, change, construction, implementation, lean, resistance, transformation.

Introduction

The lean movement in construction started around 1992 with the creation of the International Group of Lean Construction (IGLC). Since then, and especially over the past decade, organizations all over the world have been looking for ways to increase competitive advantage for the delivery of capital projects through the application of lean concepts and techniques. Some organizations have achieved pockets of excellence and others have simply failed, but truly competitive advantage has not yet been achieved.

This paper explores the main characteristics, attributes, and proven benefits of lean project delivery. It considers that the main challenges organizations are facing when trying to transform themselves into a lean organization is a combination of two aspects: (1) lack of understanding that lean project delivery implies a different way of doing business in construction, and (2) how this transformation is currently approached. This is indeed one of the reasons why only pockets of excellence have been obtained to date in construction.

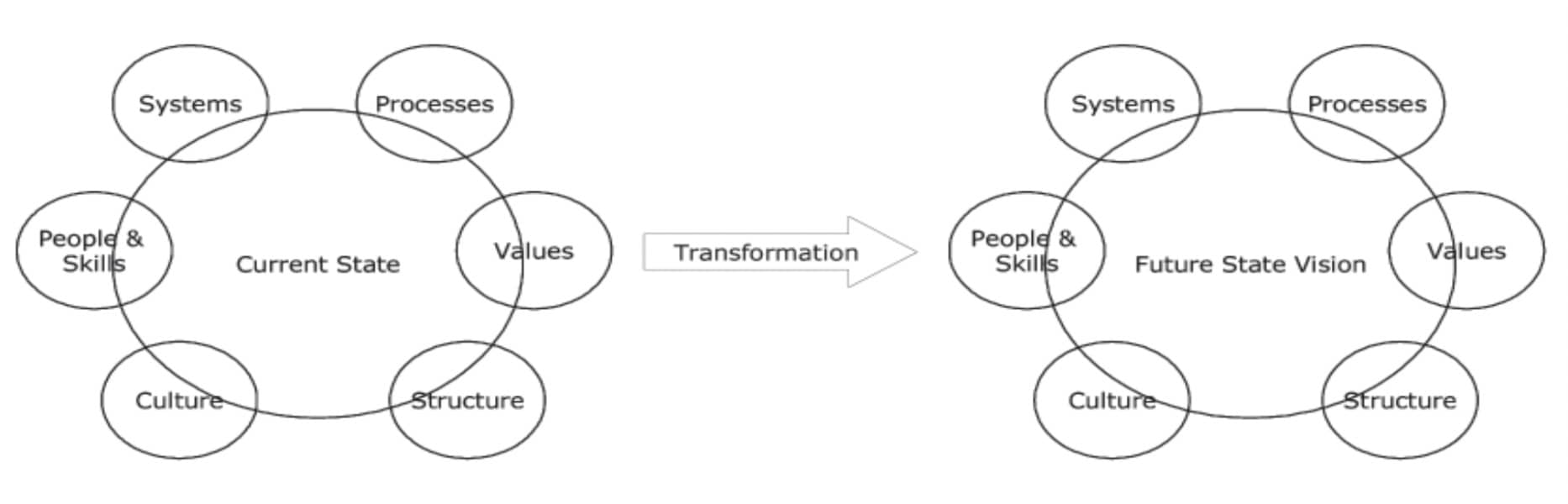

The paper proposes an approach to lean implementation that takes advantage of one of the main characteristics of construction: projects. This approach considers projects as the means for transformation from a current state to a future state vision where values, culture, processes, systems, organizational structure, people and skills support a lean working environment.

Vision, skills, resources, incentives, action plans, and team leadership are presented as key elements for a successful organizational transformation. Considering that during a lean transformation organizations move towards a collaborative environment of cross-functional, in some cases co-located teams, and project partnerships, the paper presents key concepts related to leadership skills that are not commonly used on a typical construction environment. The paper concludes with a series of recommendations for organizations that envision a transformation event towards lean project delivery.

Lean in Construction: Definition, Benefits, and Attributes

The construction industry around the world has witnessed a series of pockets of excellence as a result of the implementation of selected lean tools and techniques. Some of these tools and techniques have been taken directly from manufacturing with no modifications (e.g., 5S), others have been adapted for their use in project delivery (e.g., value stream mapping), and others have been developed exclusively for project delivery based on lean principles (e.g., Last Planner, SPS|Production Manager). The use of these tools and techniques has resulted in a range of pockets of excellence across the industry, which has proved that lean in construction provides the following key benefits:

Better fit for purpose - project outcome better meets customer value

Better control of cost, time, and associated working capital

Better and safe work environment

The main characteristic behind Lean Project Delivery is its process nature focused on defining and delivering customer value. Lean Project Delivery is therefore a process-driven approach to construction that possesses the following main attributes:

Understand value from the perspective of the customer

Concurrent product and process management

Cross-functional integration (project and enterprise levels)

Continuous improvement across the supply chain, and

Heavy-weight project leadership

Over the past decade, organizations all over the world have been looking for ways to take advantage of proven benefits and attributes of the lean philosophy in order to increase their competitive advantage for how capital projects are delivered. Some organizations have achieved pockets of excellence, and others have simply failed trying it. But truly competitive advantage has not yet been achieved. The following section presents a view of the challenge behind the adoption of lean philosophy as a new business model.

The Lean Transformation Challenge

The challenge behind Lean Project Delivery is basically being a different business philosophy. As such, it conflicts with existing ways of doing business in the construction industry, so moving from a current state to a future state vision is not simple. Implementing lean has nothing to do with lean concepts and techniques. It is really a business problem. How organizations are currently approaching implementation is partly the reason why only pockets of excellence have been seen in construction until now. Organizations are struggling to increase competitive advantage through lean because the current approach to implementation and transformation is not delivering the expected results.

Before reviewing the current approach to transformation, it is necessary to understand how organizations in general are configured. Organizations can be understood as a combination of different elements such as values, culture, processes, structure, people and skills, and systems. The implementation of lean in construction is really a 'transformation' process from a current state (the way the organization operates now) to a future state where the characteristics of these elements are redefined to enable lean project delivery and increased competitive advantage in the market (Figure 1).

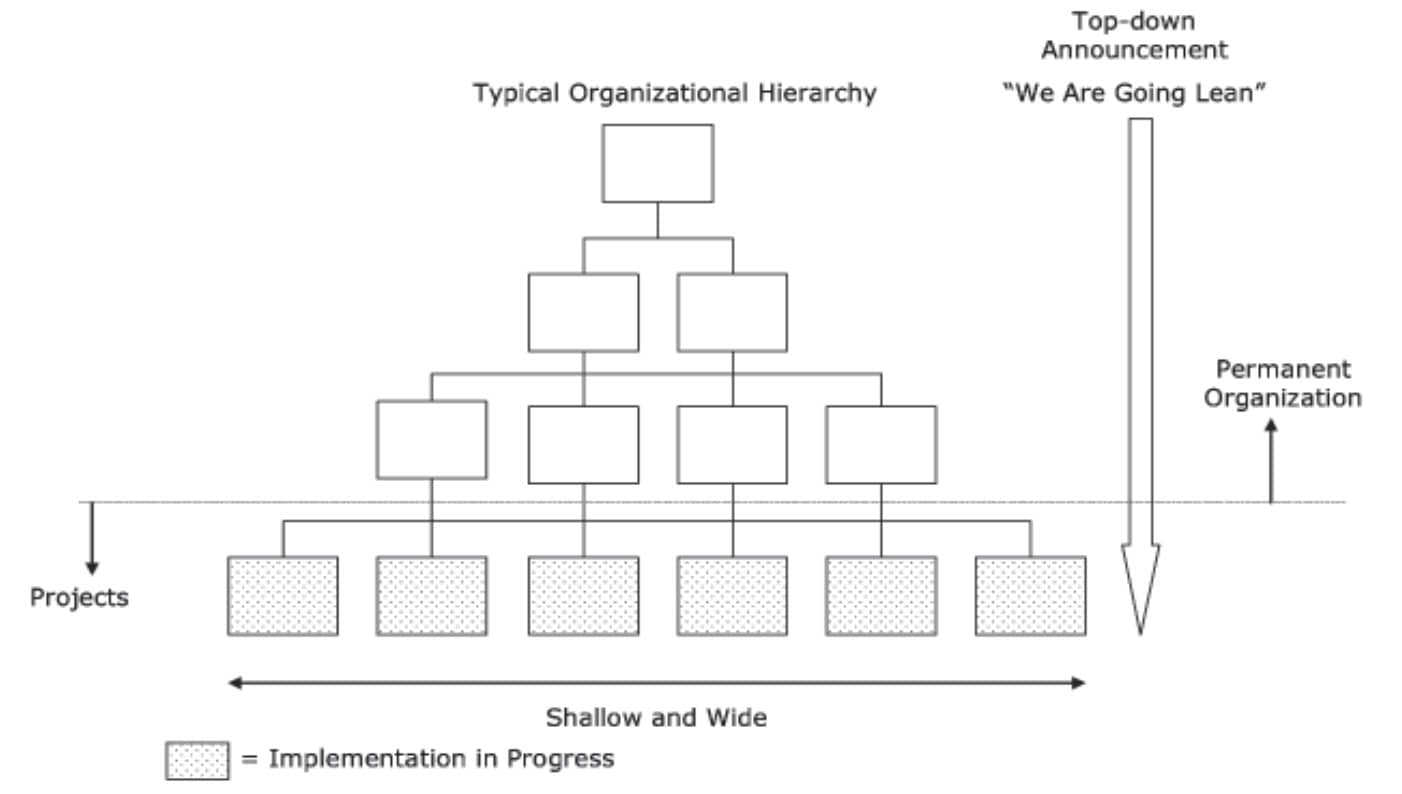

The authors have witnessed that commonly there is a desire within organizations to move quickly throughout the transformation process shown in Figure 1, sometimes due to specific demands from the market. This is pushing organizations to adopt a 'shallow and wide' implementation approach typically conceived and mandated by leadership, and then communicated from the 'top down' without proper stakeholder engagement. Typically, big announcements are made (e.g., 'we are going lean') and then the marketing department starts incorporating lean as part of how the organization operates, when in reality, nothing has been done yet within the organization, not even pockets of excellence have been achieved.

The adoption of a shallow-and-wide transformation approach (Figure 2) implies that implementation occurs in more than one project at a time at the very beginning. This imposes great pressure in the organization resulting in enormous resistance to change from the current state to the future state. Based on the experience of the authors, the adoption of this approach has proved to be counterproductive for the organization resulting in waste of time and money.

Peter Drucker (2003) stated: "For the existing business to be capable of innovation, it has to create a structure that allows people to be entrepreneurial. It has to make sure that its incentives, its compensation, personnel decisions, and policies, all reward the right entrepreneurial behavior and do not penalize it…This means, first, that the entrepreneurial, the new, has to be organized separately from the old and existing. Whenever we have tried to make an existing unit the carrier of the entrepreneurial project we have failed...This means also that there has to be a special locus for the new venture in the organization and it has to be pretty high up...There is another reason why a new innovative effort is best set-up separately: to keep it away from the burdens it cannot yet carry."

Proposed Approach to Lean Transformation in Construction

The construction industry has a key advantage compared with other industries regarding how to approach a sustainable lean transformation. This advantage is 'projects'. Yes, capital projects enable the design and implementation of temporary business systems and can be the basis for transformation, the means to create a new business model.

Typically, a construction service provider views projects only as the means for profit generation. In addition, the proposed approach views projects as an opportunity to enhance the asset value (the organization itself) through the development of new capabilities that enhance the reputation of the organization and generate competitive advantage.

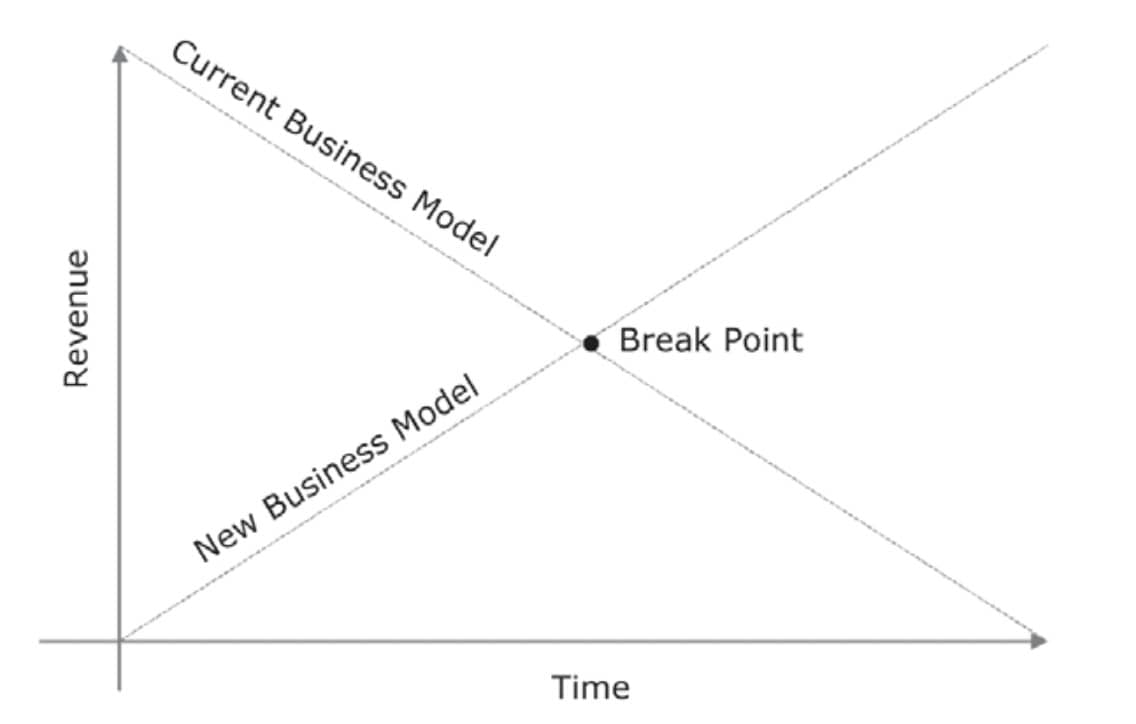

Taking projects as the basis for transformation enables a narrow-and-deep implementation approach. Therefore, the organization can achieve a better performance assessment as well as identify critical changes in structure, processes, supporting systems, etc. required to continue with a successful transformation. These critical changes really represent the start of a continuous process where old systems are disconnected, incentives are changed, processes are streamlined, and vision is reinforced through heavy-weight project leadership. Figure 3 presents a view of the proposed approach.

The main benefits of adopting this approach include:

Maintain current operations while transformation occurs. The objective is a smooth transformation.

Better control of when the break point occurs. The break point is defined here as the moment where at least 50% of projects are being delivered through the new business model.

Better control of capability development. The adoption of the new business model imposes many technical challenges for leaders and project team members.

Better decision making regarding which project is next in the transformation process. For example, companies may want to gain competitive advantage faster by selecting projects from key clients or industry sectors based on their contribution to the organization's revenue.

The impact of top-down leadership support is higher thanks to working in a= more controlled environment (e.g., one project instead of ten). A lean transformation initiative requires significant time dedicated to lead teams through change.

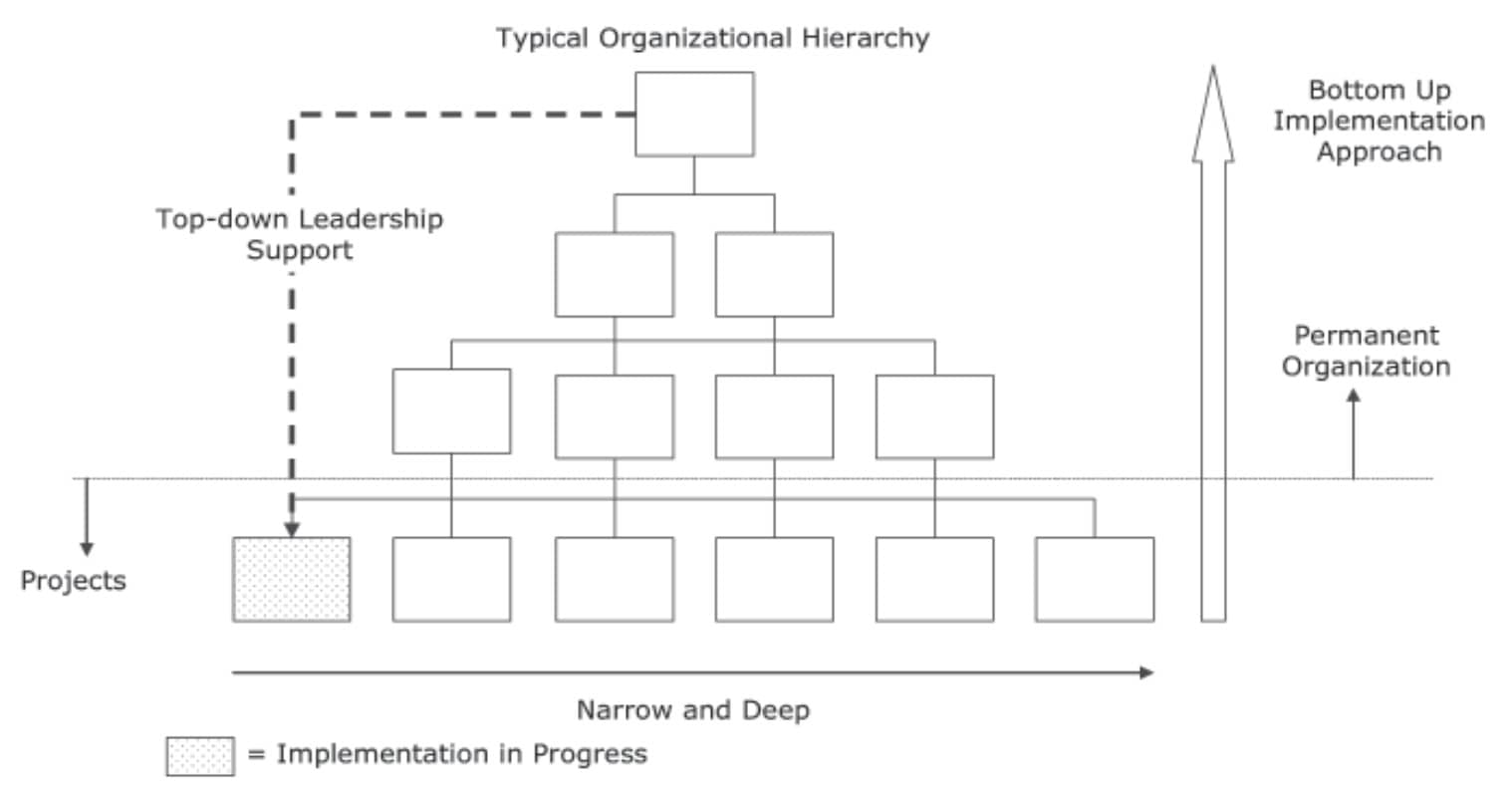

Figure 4 represents a narrow-and-deep approach to lean implementation with top-down leadership support. This approach implies that the transformation process occurs from the bottom up, in other words, from the projects (temporary organizations) towards the main office or headquarters (permanent organization).

Similar to the Toyota Production System, a lean transformation strategy such as the one presented here must follow the path of continuous improvement. To support this path, it is recommended to start a lean transformation initiative by implementing a Plan-Do-Check-Act cycle at the project level (part of the Total Quality Management movement). This will help to diagnose the situation and determine which lean techniques are required and what is the best way for the selected techniques to be implemented for that specific project environment.

Conditions for Success

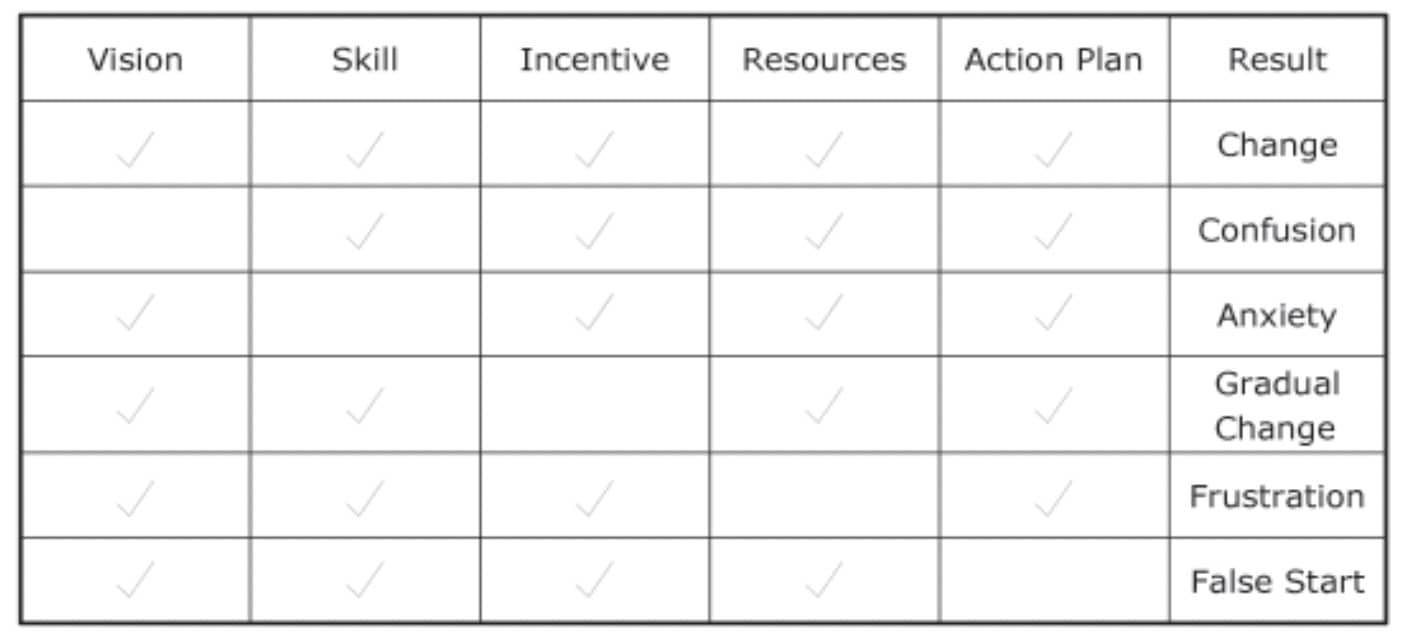

A sustainable transformation initiative requires that 5 key elements are in place: (1) vision, (2) skills, (3) incentives, (4) resources, and (5) action plan (Larson 2003). These elements should be used as a checklist prior to commencing any implementation effort. If one or more of the elements are not in place, the implementation effort will most likely fail. Table 1 outlines the probable outcome if one of the elements is missing.

Vision

Without a vision, stakeholders will be confused. Creating a vision statement sets the framework for the mission, objectives, and strategies for the implementation effort at the project level. This provides everyone involved with a clear view of what is to be accomplished, how it is to be accomplished, and how success looks like at the end of the implementation effort.

The proposed approach (narrow and deep, and bottom up) requires top management to co- create an implementation strategy with project leadership. The creation of a vision usually does not eliminate resistance to change, but rather starts exposing it. At this stage, it is common to get questions/comments challenging the need to do something different, the need to change: Why are we doing this? Why me? Why in my project? Why aren't my efforts appreciated - I delivered great profits in my last projects?

Skills

If skills are missing during any lean transformation initiative, people will be anxious. This applies to project team members, top management, and anyone that plays a role in the implementation effort. The lack of skills makes top management anxious, because they are spending money, time, and effort and may not be seeing the expected results. Skills are instilled in the selected project team through training. Training is one of the most important aspects of managing change because it fills the gaps between the current business model and the new business model.

Technical training promotes competency, and behavioral development fosters commitment. Behavioral development is therefore defined as the process through which a human being develops his/her behavior as a reaction to the adoption of new concepts, tools, and techniques.

Lack of management of behavioral development is one of the main reasons why resistance to change grows to undesirable levels during a transformation effort. To such an extent that can sabotage a whole implementation effort. The authors recommend that a way to measure implementation progress and success is defined and agreed between the main stakeholders. Goldratt et al. 1992 states: 'Tell me how you are going to measure me, and I'll tell you how I will behave'.

Incentive

If an effective incentive scheme is missing, change will be gradual. The new systems and methods of working may eventually be adopted as project teams begin to see benefits, but the change will most likely take longer than desired.

The word 'incentive' is commonly associated with monetary rewards. Despite popular belief, money is not the key motivating factor for most people, and it is also very difficult to create a monetary reward system that is equitable during a transformation effort. In fact, one of the most effective ways to motivate people is through recognition. Successes of individuals and teams can be highlighted through various corporate communication channels (refer to Maslow's hierarchy of needs later on this paper).

Resources

If resources are insufficient, frustration will be the end result. It is crucial to provide sufficient resources to support the implementation effort. Teams will need to be facilitated, individuals will need to be trained, and managers will need to be coached.

Action Plan

If a solid action plan is not in place, the likely result is a false start. In an effort to make progress, teams will start down one path of action without knowing if this is the right path. Eventually the team will either reach a point where they do not see the desired results, or do not have a clear idea of what to do next. It is therefore essential to co-create and agree a plan of action for the implementation effort with project leadership.

These 5 key elements described by Alan Larson must be implemented together with heavy- weight project leadership capable of taking teams through change. The next section presents key concepts for how to lead teams through a lean transformation effort.**

Leading Teams Through Lean Transformation

The traditional approach to managing projects and leading teams in construction employs a strategy of using centralized control to coordinate actions. During a lean transformation, the organization moves towards a collaborative environment of cross-functional, in some cases co-located teams, and project partnerships which requires leadership skills typically unfamiliar in construction.

The following quotes by Peter Drucker (2003) accurately portray the situation faced when trying to implement lean: "Organizing work according to its own logic is only the first step…The second and far more difficult one is making work suitable for human beings - and their logic is radically different from the logic of work…Making the worker achieve [his/her objectives] implies consideration of the human being as an organism having peculiar physiological and psychological properties, abilities, limitations, and a distinct mode of action".

Understanding and moulding the behaviour of individuals and teams is one of the main challenges during a lean transformation effort. Project leaders must be trained in facilitation because they are responsible for establishing milestones, communicating them, and then creating the right environment in which team members can achieve the milestones. And team members need to be trained in how to work collaboratively so they can deliver the milestones through the new approach.

This section presents a series of concepts and tools for organizations that envision a lean transformation. It describes different leadership styles, how teams are formed, different phases of change that all teams go through, and finally some thoughts on what motivates individuals.

Situational Leadership

Blanchard (1985) developed a Situational Leadership Model. Blanchard proposes that there exist two primary requirements for successful organizational development: (1) competency, and (2) commitment. For a transformation to be sustainable, competency and commitment are required.

Blanchard classifies individuals into four levels of development:

High Competence, High Commitment: Experienced at the job, and comfortable with their own ability to do the job well. May even be more skilled than the leader.

High Competence, Variable Commitment: Experienced and capable, but may lack the confidence to do the job alone, or the motivation to do it well / quickly.

Some Competence, Low Commitment: May have some relevant skills, but won't be able to do the job without help. The task or the situation may be new to them.

Low Competence, Low Commitment: Generally lacking the specific skills required for the job at hand, and lacking any confidence and / or motivation to tackle it.

Different leadership skills are required for dealing with each of the four developmental levels, and for guiding team members to the next level of development. Blanchard characterized leadership styles in terms of the amount of direction and of support that the leader gives to his or her "followers". These leadership styles are:

Directing: Required to build others' competence. Leaders define the roles and tasks of the 'follower', and supervise them closely. Decisions are made by the leader and announced, so communication is largely one-way.

Coaching: Builds both competence and commitment. Leaders still define roles and tasks, but provide less supervision and seek ideas and suggestions from the follower. Decisions still remain with the leader, but communication is much more two-way.

Supporting: Builds confidence, motivation, and thus commitment. Leaders pass day-to-day activities and decisions to the follower, providing guidance as needed. The leader facilitates and takes part in major decisions, but control is with the follower.

Delegating: Used to acknowledge competence and commitment. Leaders still monitor progress and are involved in decisions and problem-solving, but control is with the follower. The follower decides when and how the leader will be involved.

Understanding Team Development

The group of individuals which make up a new team may or may not have worked together in a team setting before. Even if they have, the new processes, supporting systems, structure, etc. may cause the team to re-experience the various phases of natural team development. Tuckman (1965) defined a four-stage model of team development including the phases of forming, storming, norming, and performing. During these various phases (Figure 5), the focus of team members tends to shift from personal needs, to the needs of the team, and finally to the efficient achievement of goals.

When groups or teams first form, people are typically on their best behaviour, trying to determine the group's purpose and how they fit in. As the group begins to work, there are usually differences of opinion, personality types, underlying personal needs and values, differences in goals, etc. that start to surface. Knowing how to lead is crucial in these circumstances.

Storming is the process of determining how conflicts and disagreements will be resolved - directly and openly, or through indirect or subversive means. Three types of issues are usually the cause of storming: (1) membership, (2) control, and (3) goals. Storming about membership has to do with a sense of belonging - being accepted, respected, and valued. Control issues have to do with decision-making authority and the ability to affect one's own destiny within the group setting. Storming about goals can include debates over the team's direction and decisions, and differences in personal stakes or interests.

If the group learns to storm effectively (listen to each other with respect, consider other's needs and interests, work together to find win/win decisions, etc.), those behaviours eventually become the group norms. If conflict is avoided or decisions are pushed through, the group will never really form into a team and ineffective practices will persist, wasting everyone's valuable time and energy. As a team moves through the various phases of team development, it will eventually become a high performance team capable of delivering the future state vision.

The Internal Process: Four Phases of Change

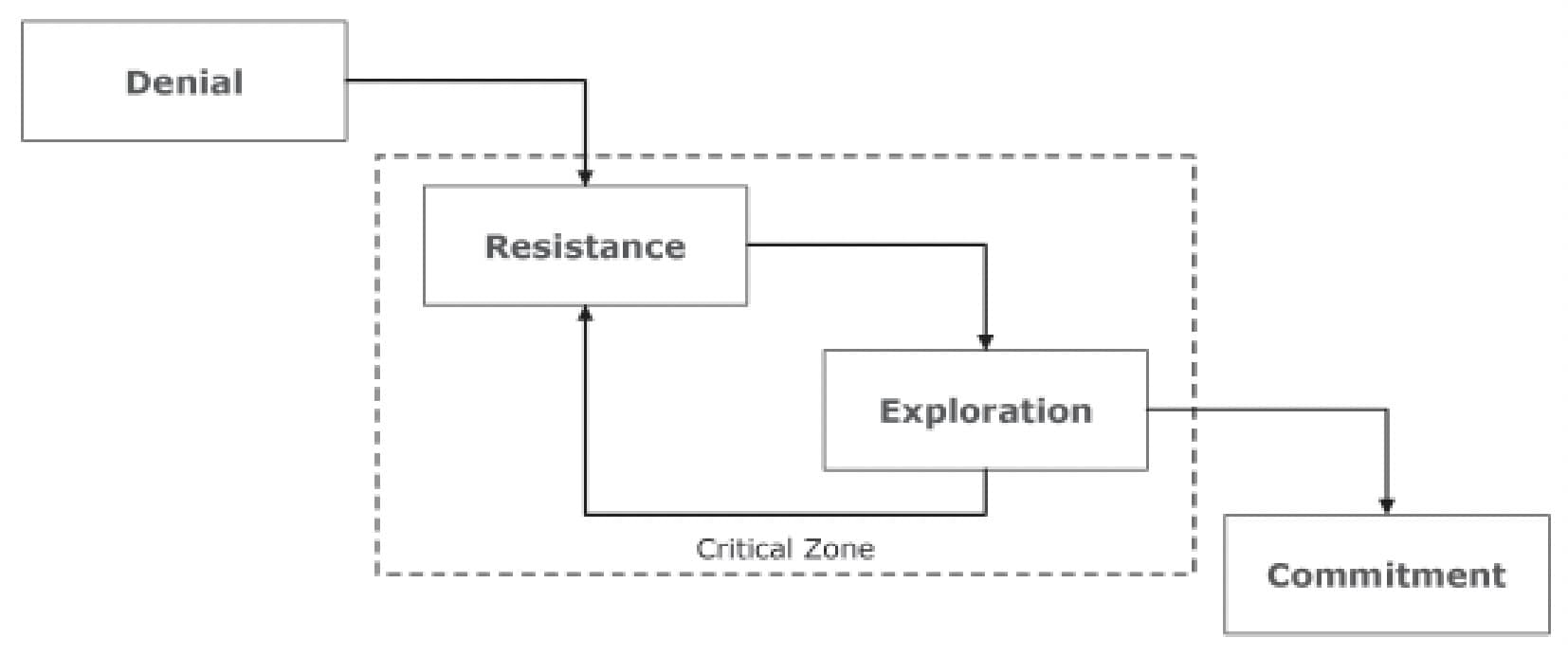

Teams are composed of individuals. And individuals are the ones resisting change. Change can occur quite rapidly but adjusting to the change can often take time and effort. Effective leadership of organizational change requires an understanding of the emotions experienced during a business transformation; and techniques to take teams through the four phases of change (Figure 6) described by Reynolds (1994).

Denial is an attempt by an individual (team or organization) to preserve the success and comfort of the past by ignoring signs that change is required. Some symptoms of denial include people avoiding the topic, appearing unconcerned, refusing to take initiative, acting like nothing is happening, or perhaps doing only routine work. Breaking through denial requires information (explain the situation).

Significant change does not happen without resistance. It is critical to welcome resistance, find any underlying issues, and address them in a timely manner. Leaders often adopt a command and control leadership style and attempt to overpower resistance by demanding compliance with authority, however, experience has demonstrated to be counterproductive resulting in increased resistance. Some symptoms of resistance include showing anger, arguing, complaining and blaming, verbally supporting the transformation effort but doing nothing, and becoming exhausted and overwhelmed. Breaking through resistance requires listening for current issues.

As people work through resistance, they become curious about the possible rewards and/ or benefits of change, and begin to explore. A spirit of learning, experimentation, and possibility develops. For example, people in exploration seek for new ways of doing things, begin to create a vision of the possibilities of the future, take risks, generate lots of ideas in support of the transformation process, and accomplish intermediate goals and celebrate milestones. Breaking through exploration requires continuos guidance to avoid the individual returns to resistance mode.

Commitment comes when individuals and teams have learned new ways of working and have assumed responsibility for making the change succeed. They understand why they have gone through the change, and experience pride and accomplishment that they have effectively completed the process of change. For example, people in commitment are comfortable and in control, reflect on what they have learned, and begin to look ahead to the next change. Sustaining commitment requires continuous support from top management.

Motivation Theory

Having a basic knowledge of motivation theories help to understand why people behave in one manner or another, and why certain incentives are ineffective for motivating specific individuals. Some basic concepts of motivational theory include: (1) the fact that all behavior of individuals, teams, and organizations is purposeful and aimed at meeting needs (although the purpose or need may not be obvious), (2) people always tend to use the best solutions they know at the time to meet their needs, and (3) for new solutions to become standard practice, they must prove better at meeting needs than the old solutions.

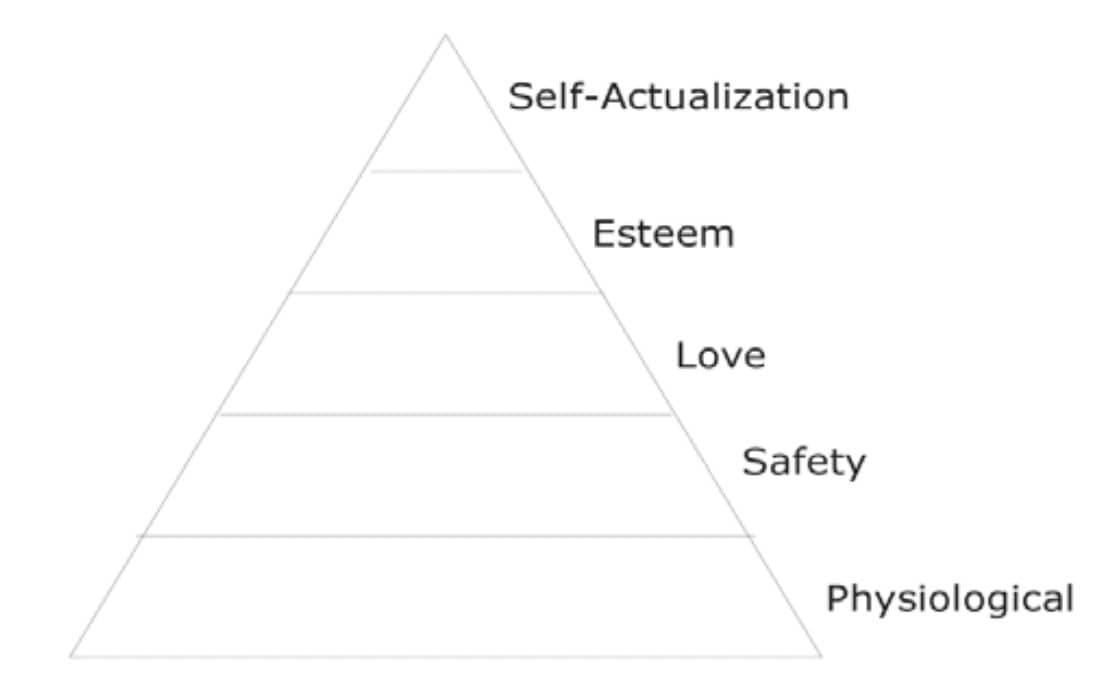

Maslow (1943) proposed that humans are motivated by unsatisfied needs, and that as more basic needs are satisfied, humans desire higher, more complex needs. Maslow's hierarchy of needs is often depicted as a pyramid consisting of five levels (Figure 7): the four lower levels are grouped together as deficit needs; the top level is referred to as being needs. Whilst deficit needs can be fulfilled, being needs are a continuing driving force. The basic idea of this hierarchy is that higher needs come into focus only after all the lower needs in the pyramid have been met.

Physiological needs are the very basic needs such as air, water, food, and sleep. When the physiological needs are satisfied, humans next turn to safety needs. Safety takes the highest priority over all other desires, and has to do with avoiding bodily harm and establishing stability and consistency in a chaotic world. Love and belonging are next on the ladder of needs. Humans have a desire to belong to groups: clubs, work groups, sports teams, family, etc. We need to feel loved and accepted by others.

Maslow (1943) defined two types of esteem needs. First is self-esteem which results from competence or mastery of a task. Second is the attention and recognition that comes from other people. The need for self-actualization is the need to make the most of one's unique abilities. People who have all their lower needs satisfied can then focus on maximizing their potential. Whilst other needs can be met fully, self-actualization is seen as a continuing driving force for self-improvement. Current conditions around the majority of the globe are such that humans are not as concern about physiological and safety needs. Humans are moving directly to esteem and self-actualization needs. This is the reason why monetary rewards are not always a good incentive. These days, most people look for recognition within an organization.

When individuals exhibit signs of resistance, it indicates that one or more of their needs are not being met. The important thing is to find the underlying cause of the resistance, and if possible, make an attempt to address the unsatisfied need. Lareau (2000) stated: "The leader must create conditions that allow each member of the organization to maximize his/her need satisfaction while fulfilling the objectives of the organization".

Conclusion

Implementing lean has nothing to do with lean concepts and techniques. It is really a business problem. This paper has proposed a strategy for how to succeed implementing lean. The strategy considers a narrow-and-deep and bottom-up implementation approach with projects as the means for transformation. The benefits of this approach include the ability to maintain current operations while transformation occurs, better control of the implementation speed, better control of capability development, better decision making regarding which project is next in the transformation process, and greater impact of top-down leadership support thanks to working in a more controlled environment (one project instead of ten).

This strategy can be adopted by owner operators who envision a different way of delivering their capital projects or by construction service providers seeking for increased competitive advantage through the adoption of lean project delivery. The authors are currently working on several implementation efforts where the proposed approach is being adopted. Future papers will report details behind these experiences.

Footnotes

Roberto Arbulu - Implementation Leader, Strategic Project Solutions Inc., 1040 Battery St., San Francisco, CA 94111, USA, Phone: 1-415-362-3200, email: rarbulu@strategicprojectsolutions.net

Todd Zabelle - President, Strategic Project Solutions Inc., 1040 Battery St., San Francisco, CA 94111, USA, Phone: 1-415-362-3200, email: tzabelle@strategicprojectsolutions.net

References

Blanchard, K., and Zigarmi, P., (1985), Leadership and the One Minute Manager: Increasing Effectiveness through Situational Leadership, Blanchard Management Corporation, New York.

Drucker, P., F. (2003), The Essential Drucker: The Best of Sixty Years of Peter Drucker's Essential Writings on Management, Harper Collins Publishers, New York.

Goldratt, E., M., and Cox, J., (1992), The Goal: A Process of Ongoing Improvement, North River Press, Inc.

Lareau, W., (2000), Lean Leadership: From Chaos to Carrots to Commitment, Tower II Press, Indianapolis.

Larson, A. (2003), Demystifying Six Sigma: A Company-Wide Approach to Continuous Improvement, AMACOM, New York.

Maslow A. H. (1943), Theory of Human Motivation, Psychological Review, 50, 370-396

Reynolds, L. (1994). Understanding Employees' Resistance to Change. HR Focus, 71 (6), 17.

Tuckman, B.W. (1965), Developmental Sequence in Small Groups, Psychological Bulletin, vol. 63, 1965, pp. 384-399.