Abstract

The ever-increasing lead time for products (including materials and permanent equipment) required to deliver a capital project results in increased project delivery costs and operating costs for owners, not to mention the associated loss of revenue and related lost opportunity cost.

This paper outlines the cost of long lead time and provides the reader with a technical framework for understanding why long lead time is prevalent and what action can be taken to address it, including the application of value stream optimization.

Keywords: Cycle Time; Lead Time; Process Time; Value Stream; Modularization

Introduction

The saying “time is money” is known to many, but not always well understood as to why the relationship between time and money exists. From a production perspective, time is money because time impacts control of time to market. It often results in loss of revenue and increases cost due to unnecessary handling, holding and preservation of inventory (including stocks and work-in-process, or WIP) not to mention the potential for damage, theft and obsolescence. In the most extreme examples on the most complex projects, stocks explode to the point that construction crews have difficulty knowing what is and is not onsite, leading to multiple orders or double manufacturing. Time and these related costs also increase the need for more cash, resulting in lost opportunity, additional financing cost, etc. Therefore, lead time compression, the associated supply process improvement and better management of existing stocks / WIP are important elements of any supply chain optimization effort as well as supplier development programs for capital projects.

The ever-increasing lead time for products (including materials and permanent equipment) required to deliver a capital project or maintain operations results in increased project delivery costs and operating costs for owners, not to mention the associated loss of revenue opportunities. It is not uncommon to have a lead time of over 24 months and even greater for major equipment items, i.e. pumps, transformers, valves, etc. To give the reader a sense of the magnitude of certain lead times: in the oil and gas sector, lead times of as long as 48 months have been quoted for certain types of oil field equipment used in offshore field development, as have certain items used for the construction of large LNG plants.

One often overlooked and significant area of cost reduction is lead time compression. As stated above, excessive lead time has many hidden costs. Perhaps the most significant is the loss of ability to make decisions as design develops. At issue is long lead time, creating the need to procure items in advance of when it is optimal to meet demand and associated dates. The result is value loss due to 1) reducing long-term operability opportunities – aka settle for a lesser option, 2) the need for “work-arounds” in the way of over-engineering to compensate for less than desirable solutions, 3) the complete abandonment of a design and potential discardment of the associated materials due to an undiscovered flaw in the work to date, including any rework associated with it and finally, 4) the cost of change orders resulting from “design change after fabrication.”

Owners who are required to make decisions too early to procure such pieces of materials and equipment because of lead times may have to make these choices in the presence of considerable uncertainty, with potentially significant value loss. One example is having to make choices on the oil and gas handling capacity of equipment, before full knowledge of likely production rates are confirmed. Another is having to determine the capacity of data centers with full acknowledgement that the farther out the forecast, the less accurate the demand for them will become. This can result in significant oversizing of equipment and additional unnecessary cost, because the decision timing was dictated by lead times rather than the availability of the necessary information to make an informed decision.

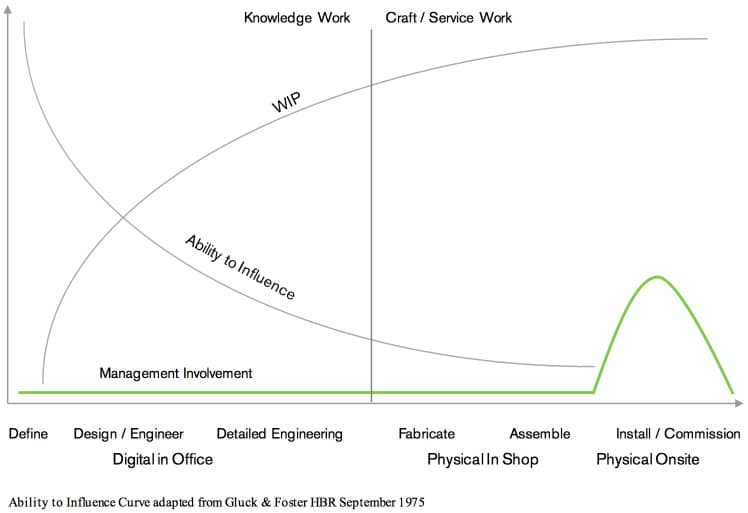

Figure 1, adapted from Harvard Business Review article “Managing Technological Change: A Box of Cigars for Brad,” illustrates how long lead times force design decisions to be made too early in the project life cycle, increasing cost and time duration due to unnecessary amounts of WIP and tying up unnecessary working capital, as well as reducing agility. As procurement commitments are made, WIP begins to amass. As WIP amasses, the ability to influence or make other decisions is reduced.

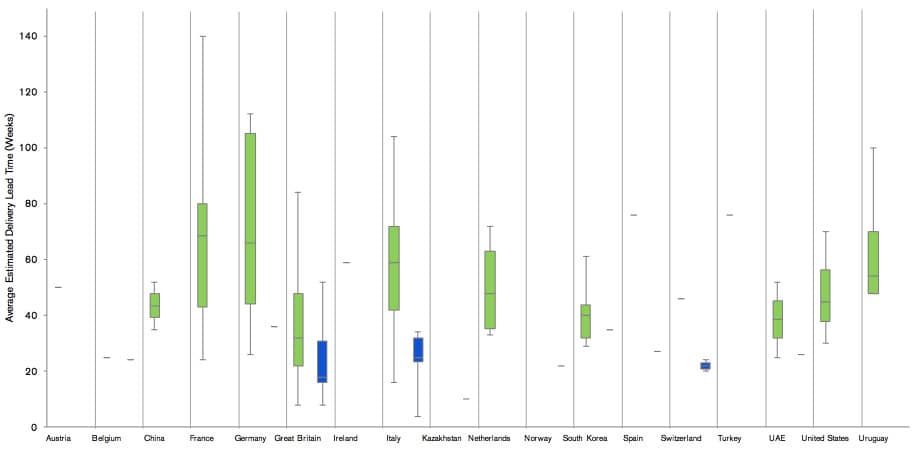

Compounding the problem is the need to coordinate differing lead times for various products that must come together or be integrated at or near the same time during fabrication, assembly and installation. Synchronization being the goal, if one item is too early it must wait for the other and may result in loss of capacity use and the associated cost, potential re-sequencing of activities that may result in sub optimizing other elements of the project, as well as schedule delay. Projects employing modularization as a strategy for speedy delivery often amplify the damaging effects of poor synchronization that exist in capital project supply chains. Figure 2 provides a sanitized field example of the lead time variations in a project employing a modularization strategy.

Companies that do recognize the cost of long lead time regularly adopt strategies such as standardization of product design, as well as funding inventories of raw materials or even finished goods. Some owners are of the opinion that greater collaboration is needed, while others feel they should stay clear of a supplier’s business. However, this may be short-sighted and even counterproductive. In some instances, owners are more involved in the configuration of the supply process than they may realize. The procurement of inbound materials by owners as the means to reduce purchase cost, minimize tax, etc. is one such example.

Owners are led to believe that lack of standardization and desire for customization is the basis for long lead time. This is completely logical, as the solutions commonly proposed to reduce lead times are to move from an engineered-to-order (ETO) product to a made-to-order (MTO) product, which eliminates engineering duration from the overall cycle time as well as process variability caused by product variation during the “make” process. Another commonly proposed solution is to move from ETO to made-to-stock (MTS), which can eliminate engineering, fabrication and assembly durations from the overall cycle time and associated variation. Though logical, oftentimes there is good reason why various products need to be ETO.

Though well-intentioned, these solutions typically do not deliver optimal results and may even cause unintended consequences. The reason being is that there is a lack of a robust scientific framework, as well as lack of an associated approach upon which to undertake lead time compression. The trade-off between having a custom product versus a standardized product is multifaceted and must be thoroughly understood. However, the comparison must be based on what is possible, rather than the face value of the current state.

Why Long Lead Times Exist

The ability to mandate lead time is a very valuable sales / negotiating strategy to a product supplier (processor or manufacturer) as well as a service provider (engineering firm, fabricator, installer, etc.). Typically, vendors add time buffers to lead times to enable leveling flow through their production systems, and in so doing, reduce cost, apply pressure on buyers to place orders, and in some instances, establish the basis for future compensation and claims. In the most constrained cases, vendors may inadvertently offer scarce capacity to multiple buyers to ensure high resource utilization, necessitating a lead time buffer.

For instance, a fabricator may convince an owner of a stated lead time. This lead time may be so long it requires fabrication to start prior to design being complete. In this case, we must ask, is the design late (often what owners are told) or is fabrication starting too early? Such is the case of so-called “modularization” approaches that look to move fabrication and assembly offsite to more efficient purpose built facilities. Due to the added time and complexity of logistics requirements, work almost always must commence earlier in the project delivery process.

Starting this work earlier in the process oftentimes results in reduced time for engineering and the unintended consequence of rework during fabrication, assembly and installation resulting from the reduced time for engineering.

Technical Framework

Operations Management / Science, a well-established field of engineering science [2 – 4], provides the framework for understanding why products cost what they cost, why lead times are what they are, and how to reduce cost and lead time. This includes the necessary technical approach and associated mathematical algorithms.

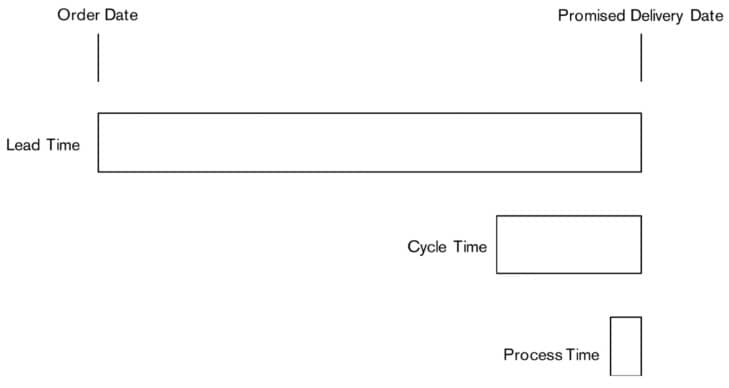

At the most fundamental level is the understanding that three key elements of time exist: lead time, cycle time and (raw) process time. Recognizing the difference between each of these elements of time and their relationship is the first step in learning how to compress lead time (and the associated cost). It is also important to understand how various decisions extend lead time and result in other unintended consequences.

To remind the reader:

Lead time is the time allotted by a supplier for the production and delivery of the part or equipment ordered [2, pp. 230].

Cycle time is the average time from when a supplier authorizes work to be started on producing the equipment to when it exits production [2, pp. 230].

Process time is the time a part or piece of equipment spends actually being worked on in production until it is finished, eliminating any time spent in holding and inventory waiting to be worked on [2, pp. 230].

A quick analysis of the ratios comparing lead time to cycle time, cycle time to process time and process time to lead time quickly represents the significant value compressing lead time offers. Following our earlier example of a piece of offshore equipment, the lead time was as long as 48 months, the cycle time was about 18 months, and the process time was less than three months, illustrating what the qualitative relationship shown in Figure 2 holds. This does not account for the additional time buffer that the owners are building into their schedules to absorb any potential delays.

Such is the case for items needed to build a data center. A recent study concluded that though the average lead time for critical electrical and mechanical data center equipment was 15 weeks, the average cycle time was two weeks. In other words, this is an average ratio CT / LT equivalent to 13%. The remaining 87% represents work sitting in queues (WIP) and time buffers added.

These examples clearly expose the significant opportunity that exists in project supply flows to reduce lead times to match cycle times, and in so doing, enable more effective synchronization of supply with actual site demand.

Value Stream Perspective

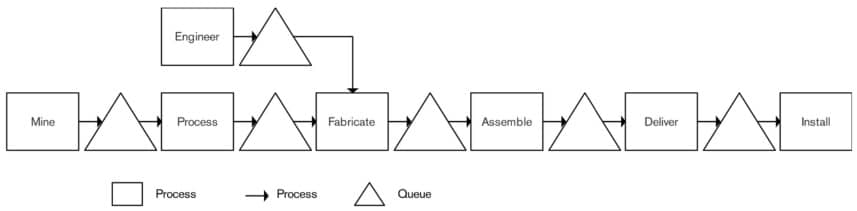

Effectively reducing lead time requires an understanding of value streams, including how they are configured and how they behave. The term ‘value stream’ refers to all the necessary actions required, starting with extraction of raw materials (including engineering), to delivery of the final product, to the consumer of said product.

Figure 4 below depicts the flow of the majority of physical goods made today. The process starts with extraction of base materials then progresses through various sub-processes including processing, manufacturing / fabrication, subassembly, assembly and finally installation commissioning and startup. Each of these sub-processes form their own production system and usually serve multiple customers (multiple projects / multiple enterprises).

In addition to the transformational (physical production) processes contained within a value stream, there also exists various business processes, i.e. purchasing, contracting, accounting, etc. Though not directly a contributor to the realization of value from a production perspective, these processes can have significant impact on lead time. It is not uncommon for the issuance of a purchase order to form the means for releasing production, for a purchase order to omit the required sequence of fabrication and for various commercial and legal agreements to extend lead time. This may be accentuated by strategies to reduce cost, including buying in bulk as well as complicated bidding and tendering processes aimed at securing more favorable pricing without regard for the eventual “all in” cost (the price is not the cost). Translating all these value stream considerations into a high-level Production System, as shown in Figure 3, leads to an understanding of where time in queues builds up because of the different business process activities outside the actual transformational processes required to produce the equipment. This understanding also points to the opportunities for optimizing the value stream through reducing the time in queues.

Value Stream Optimization

The identification of various activities that do not need to be performed and / or activities that can be performed more efficiently (within the context of business objectives) is the primary focus of value stream optimization. This includes determining the ratio between Lead Time and Cycle Time and why the time buffer is there, why it is the size it is and whether it can be reduced or substituted by another form of buffer. The same is true for the ratio between Cycle Time and Process Time, including determining the amount of variability and the associated buffers (capacity and inventory) that are present in the value stream. From a risk management perspective, the trade-off between risk of delay vs. WIP needs to be examined, as risk of WIP is rarely understood in the engineering and construction industry.

This is done through a framework of mathematical equations including Little’s Law, Cycle Time Formula and the VUT Equation, enabled through tools specifically designed for performing this type of analysis.

Applying the Technical Framework

Compressing cycle time requires a focus on the actual production or transformation process, wherein compressing the time buffer added to the cycle time to establish the lead time requires understanding of business drivers including demand planning and capacity leveling / optimization, among others.

To best understand how the various elements of time are occurring, adoption of the production system perspective is needed. The key idea here is that the focus is on physical transformation activity versus administrative and functional activity. Administrative and functional activity are only considered if they impact the physical transformation activity.

Using a value stream perspective allows for the identification and quantification of the above elements of time along with opportunities to compress the overall lead time. The value stream perspective allows for understanding the implications related to inbound supply objectives and strategies on the part of the supplier and their suppliers.

Product suppliers and service providers generate value for their shareholders by optimizing their production system, not the project production system. The way a product supplier or service provider optimizes their production system is often in contrast to what is in the best interest of the consumer of their product or service. Product suppliers and service providers are most often concerned with maximizing revenue, profit and use of cash through optimizing use of their capacity and inventory.

Capacity comes in many forms (labor, equipment and use of space) and is a source of cost to the supplier. Nearly all fabrication operations must pay close attention to the cost of capacity and optimize for capacity utilization. Finished goods inventory is kept at a minimum to optimize space, so goods are shipped as soon as completed rather than as soon as needed. Trailer capacity is optimized by shipping as much as will fit the trailer, rather than what is required by the customer. Above all, the workforce is kept producing at maximum efficiency possible regardless of whether or not the output of that effort can be readily transformed into a usable product at the time it is required, resulting in excessive WIP, long lead-times or late deliveries. Suppliers also optimize for working capital by shipping first what generates the most revenue rather than in the sequence that makes sense for the customer.

Inventory is time. Whether an item is waiting to be worked on, is being worked on, is waiting to be delivered, is being delivered to the consumer, waiting to be consumed or is being consumed, time and the above costs associated with time are being expended. Therefore, reducing inventory is the same as reducing time, and as stated above, time is money.

Owners can begin by understanding the ratio of lead time to cycle time or the difference between the amount of time from order to delivery versus the actual time in production. Often, long lead times can be understood to be the consequence of suppliers optimizing the use of their existing equipment and labor to maximize use of capacity, and minimize inventory on-hand. In situations that have low volume, high-variety discrete manufacturing, lead times can become large multiples of process time because of the additional time the supplier incurs in equipment setup, and switching between orders to serve different customers. Once owners understand this, they can work with the supplier to agree on the necessary changes in the production system, which, as mentioned before, can be deduced by focusing on understanding whether the size of the lead time is an appropriate size of buffer for the system, whether it can be reduced, and / or whether it can be substituted by another buffer. However, this requires the owner taking an active role in shaping supplier production systems via supplier development programs. Too often, capital project supply chain management is reduced to a purchasing and procurement activity, resulting in lost opportunity.

By way of example, if the supplier is induced to increase capacity, that can be one way of reducing lead time. Another way might be to reserve or schedule production capacity at given times, to assure a not-to-exceed lead time. If the supplier is quoting long lead times because of high product variety in their production system, stipulating a maximum total wait time for production jobs can be a way to establish control over the total WIP and the total waiting time for a production unit in the supplier’s manufacturing line.

Conclusion

The ever-increasing lead time for products (materials and permanent equipment) required to deliver a capital project results in increased project delivery costs and operating costs for owners, not to mention the associated loss of revenue and related lost opportunity cost.

Often overlooked, an area of significant cost reduction opportunity is lead time compression. Lead time compression can be effectively achieved through the application of Operations Management / Science, whereas attention is placed on production or transformational processes and associated throughput, WIP, cycle times and sources of variability.

References

F.W. Gluck and R. N. Foster, “Managing Technological Change: A Box of Cigars for Brad”, Harvard Business Review, September 1975.

W. J. Hopp and M. L. Spearman, “Factory Physics”, Third Edition, Waveland Pr. Inc., 2011.

P. M. Morse, “Queues, Inventories, and Maintenance: The Analysis of Operational Systems with Variable Supply and Demand”, Dover, 2004.

R. W. Schmenner, “Production/Operations Management: Concepts and Situations”, Science Research Associates, 1987.

About the Authors

Todd R. Zabelle

Todd Zabelle is the Founder and CEO of Strategic Project Solutions, Inc. (SPS). Prior to founding SPS, Zabelle founded Pacific Contracting. Established in 1993, Pacific Contracting was recognized in the mid 90’s for its use of various innovations including Lean Construction and Virtual Design & Construction. In July 1998, these efforts were acknowledged in the UK Government’s Re-Thinking Construction report.

Over the past two decades, Zabelle has authored numerous papers on the topic of optimizing engineering, fabrication and construction. These papers have been published various in technical journals, presented at numerous conferences around the world and cited by several other authors.

Matthew Parsons

Matthew Parsons is a Partner in McKinsey & Company’s Philadelphia Office, and brings his extensive experience in the Global Energy and Materials Sector, Corporate Risk Management and Capital Productivity to the Institute. He currently leads McKinsey’s Americas Capital Projects and Infrastructure Practice, which assists owners and contractors to deliver mega projects and portfolios of smaller capital investments more effectively.

Prior to joining McKinsey, Parsons served as a submarine officer in the U.S. Navy for 10 years and held various roles related to the construction, operation and maintenance of naval nuclear power plants. His experience includes three years forward-deployed in Guam as the Engineer Officer of the USS San Francisco, responsibility for the safe operation of the ship’s 165 MW pressurized water reactor plant, as well as the training and qualification of its 67 nuclear operators.

Parsons earned a B.S. in Control Systems Engineering from the U.S. Naval Academy and an MBA in Finance from the University of Pennsylvania’s Wharton School, where he was designated a Palmer Scholar and Siebel Scholar.