ABSTRACT

Fabrication is a vital part of the extended production system for a construction project. As shop fabrication is a type of manufacturing and ‘lean thinking’ arose in manufacturing, use of lean concepts and techniques in the management of fabrication processes would seem to be a natural and beneficial application.

Fabrication can be divided into pre-manufacturing, manufacturing, and post- manufacturing. In a separate paper, the authors have reported the application of lean ‘rules and tools’ to the manufacturing of precast concrete. This paper presents an overview of the entire intervention, which confirms the applicability of lean concepts and techniques to the management of fabrication processes, and illustrates the benefits achievable in improved management of demand, reduced cycle time, greater productivity, heightened work force involvement, and increased revenue and profitability. Suggestions are made for future research.

Keywords: cycle time, fabrication, flow, lead time, Last Planner, lean production, management, pull, production system design

INTRODUCTION

This paper reports the results of an experiment in lean production carried out by Strategic Project Solutions, a management consulting firm, working with Malling Precast Products Ltd., a subsidiary of the O’Rourke Group, located in Grays, Essex, United Kingdom. The Lean Construction Institute participated in shaping and carrying out the experiment. The experiment was initiated as part of a larger effort to develop a standard product and process model of multi-story precast car parks for BAA, formerly known as British Airport Authority.

Buildings, factories, and bridges are composed of many components, some of which are available off-the-shelf, while others must be made-to-order. Such components or products can be differentiated with reference to the customer order decoupling point; i.e., that point where the customer order enters the production process. Accordingly, products can be differentiated as made-to-stock, assembled-to-order, fabricated-to-order, or engineered-to- order (Wortmann et al. 1997). Engineered-to-order products pose special difficulties for construction project management. Long lead times rob design of time for generating value and constrain construction timing and pace. Precast concrete is a type of engineered-to- order product. The intervention at Malling illustrates what can be done with such ETO products to reduce lead time and thus minimize project disruption and constraints.

The first section of the paper presents an overview of the intervention. A ‘lean’ strategy for shielding the fabricator from demand uncertainty is presented in the second section. The third section describes how the pre-manufacturing (aka ‘make ready’) process was changed, and how lean concepts and techniques were applied to that process. The fourth section describes how the manufacturing process was changed. The fifth section presents the results achieved. A final section draws conclusions and suggests further research.

AN OVERVIEW OF WHAT WAS DONE

The Malling experiment involved numerous initiatives, some of which extend beyond the scope of this paper. Below are some of the most important actions taken or initiated.

-

Critical Success Factors were established focusing attention on means rather than results (Johnson and Bröms 2000).

100% Reliability of information and product delivery

Lead time towards zero

Six sigma quality standard

Zero safety incidents

Continuous & sustainable recommendations for improvement by all team members -

A 5S initiative was implemented and WIP reduced to the minimum to better understand the flow of work through the production areas setting the stage for physical reorganization into cells.

-

The factory was reorganized from a functional structure into cross functional production cells, each of which was responsible for a specific product or family of products.

-

Work flow through production cells was structured for flow and value; i.e., for minimum cycle time and for a production rate equal to customer demand rate. (Womack and Jones 1996; Ballard et al. 2001)

-

Material deliveries from suppliers were reduced from large batches to weekly or even daily deliveries. Supplies previously issued from a central storeroom were distributed to production cells and controlled through a min/max process.

-

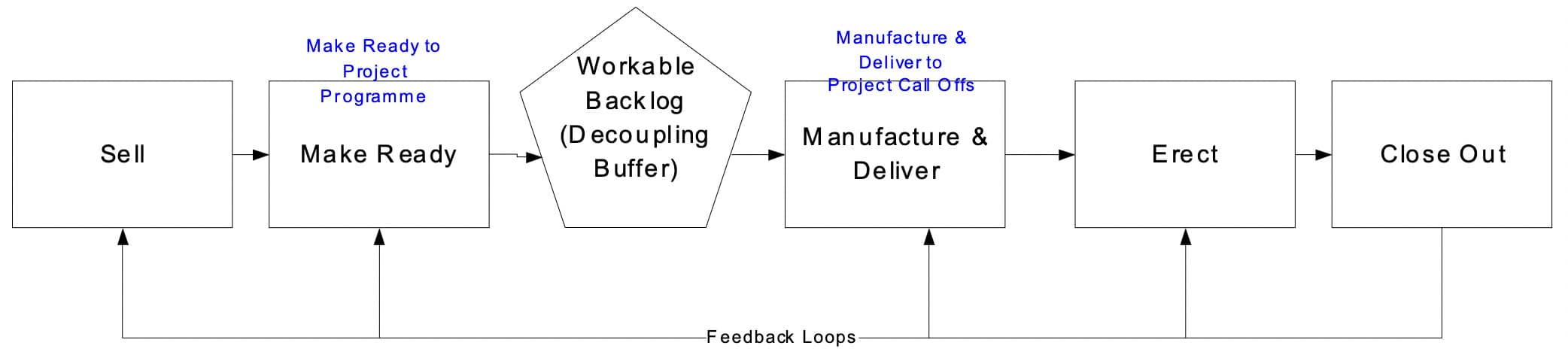

The overall work flow through the factory was structured around a decoupling buffer (Figure 2) in response to low demand reliability from projects.

-

First run studies (Howell and Ballard 1999) were initiated as the final step in a make ready process, prior to manufacturing.

DECOUPLING BUFFER

Perhaps the fundamental issue for a fabricator serving the construction industry is uncertainty of demand. In a study of industrial piping done for the Construction Industry Institute (U.S.) in the mid-90s (Howell and Ballard 1995), the first author was made privy to a fabricator’s production schedules. Analysis revealed that production schedules as little as two weeks ahead failed to predict actual workload on the shop. Indeed, the failure was so complete that almost no items were on both lists! In such conditions, fabricators can be excused for trying to protect themselves. The traditional ploy has been to build a backlog of orders, often at risk of overselling their capacity in a time period, to increase the probability that some of that booked work will actually materialize each week.

However well that strategy works for fabricators, it is apparent that it is far from an optimum solution for all parties. The principal disadvantage for customers is increased lead time for placing orders, which may rob project architects and engineers of time for generating design alternatives that add greater value to their customer, and may constrain timing and sequence of construction.

The best solution would be to improve demand reliability on the part of the construction projects that are the customers of fabricators. While tested methods for doing so are available (Ballard 2000), their implementation is not within the power of fabricators acting alone, and are not likely to entirely eliminate demand variability. A next best or supplementary solution is for the fabricator to build a buffer that absorbs variability (delays and advances in needed deliveries) that costs less in both money and time to all parties than does a buffer of customer orders.

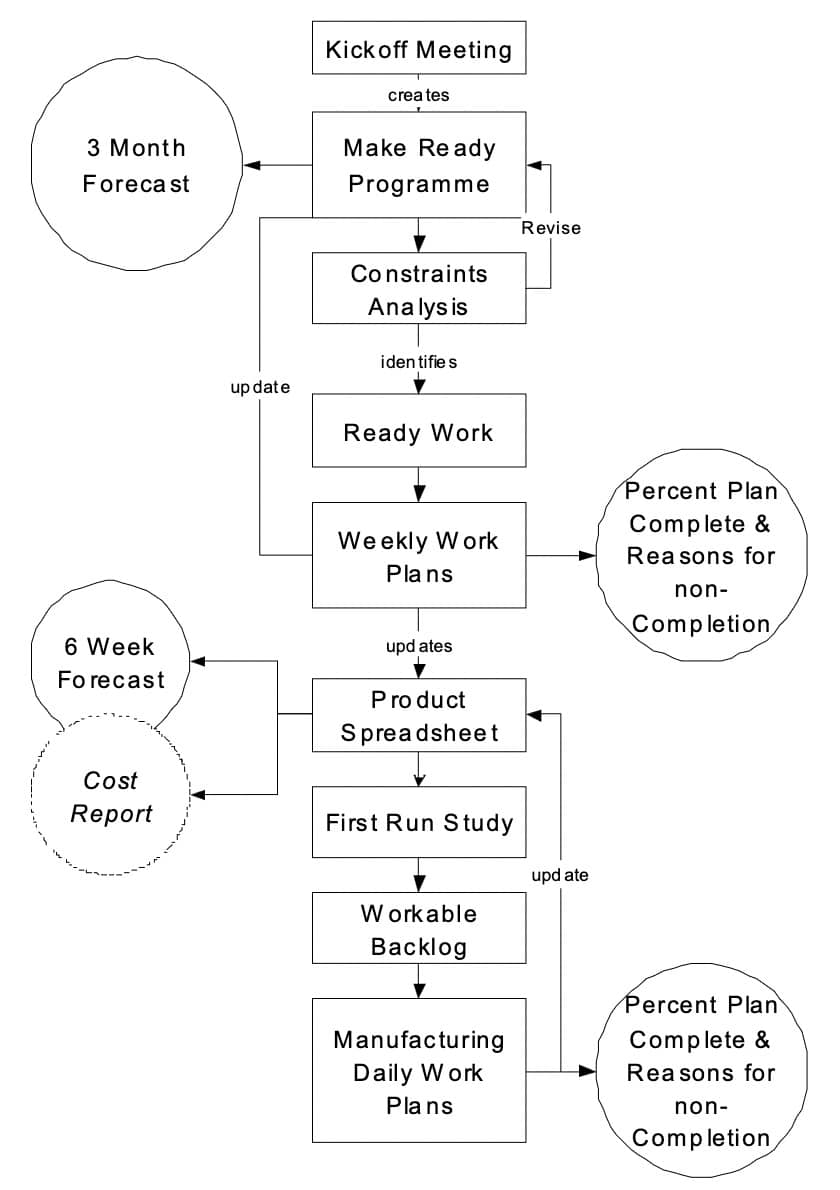

Lean construction has a multi-level approach to managing uncertainty, in this case, uncertainty or variability of demand or load. The strategy adopted at Malling for shielding the fabricator from demand uncertainty was to first build a decoupling buffer4 between pre-manufacturing and manufacturing, as shown in Figure 2. Customer orders for individual precast concrete elements were made ready to project schedules, but were manufactured in response to project call offs received one week prior to needed delivery.

In this case, relatively little money is spent making a precast element ready to be manufactured, so the natural choice is to build a buffer of information rather than a pile of precast walls, columns, or beams. Further, unlike increasing the backlog of customer orders, the decoupling buffer strategy does not increase customer order lead time, and thus does not require the customer to pay a penalty in order to access fabricator capabilities. If in no other way, the decoupling buffer strategy is lean because it generates value for customer and producer, while minimizing waste in the production system as a whole5.

The second element in the strategy for managing demand is progressively more accurate forecasting. This is certainly not an unusual technique for fabricators, but combined with the decoupling buffer proves to be quite effective. By adjusting its load forecast to changes in project schedules, Malling was able to better match load and capacity, thus allowing greater utilization of existing capacity (see Figure 7) and reducing the time in advance of needed delivery customer orders must be placed.

MAKE READY PROCESS

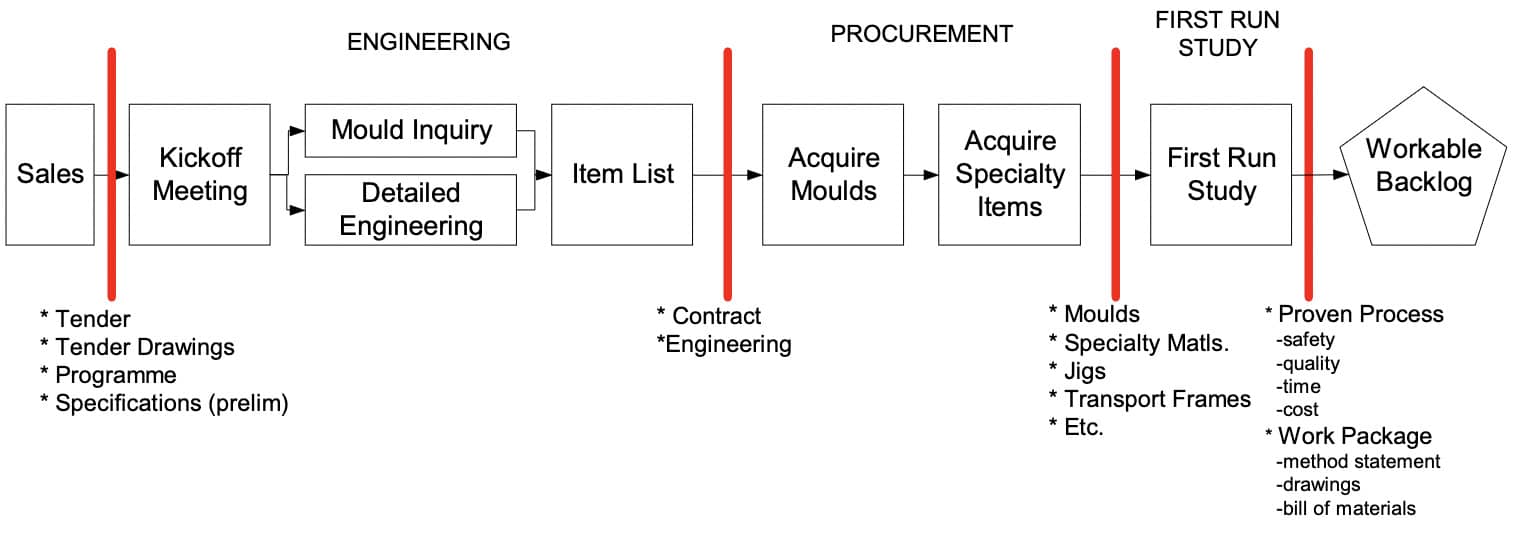

As shown in Figure 4, the make ready process was structured in a series of phase gates, with release criteria specified for each gate. For example, in order to proceed through the first gate, from Sales to Engineering, the tender, tender drawings, programme, and initial specifications were required. The make ready process proper was initiated by a Project Kickoff meeting, after which engineering detailing and mould design were developed in tandem. A list of precast elements was produced (elsewhere called a “product spreadsheet”) that included design details, bills of material, sources, weights, etc. Successful passage through the second phase gate triggered acquisition of moulds and of specialty materials. After the third phase gate, a first run study was performed for each type of precast element to assure performance capability as regarded safety, quality, time, and cost6. Where possible, first run studies were incorporated into weekly work plans two weeks prior to the first scheduled delivery of that type of precast element. Once the manufacturing operation had been successfully designed through the first run study, the precast elements using that operation design were released into workable backlog, and thus eligible for inclusion on manufacturing’s weekly work plans, awaiting receipt of call offs from the project.

PROJECT KICKOFF MEETING

Even though Malling typically fabricated precast products for projects being executed by its parent company, O’Rourke, there had previously been difficulty coordinating between fabrication shop and engineering, upstream of manufacturing, and between shop and site,

on the downstream side. One change introduced to correct that problem was kickoff meetings for each project, involving engineering, shop, and site. The first such meeting was held May 17, 2001. The comments below are excerpted from a journal kept by the first author to record the intervention at Malling:

“Friday, May 17, 2001

We had agreed earlier in the week to begin holding Kickoff Meetings for each new project. The first Kickoff Meeting was held this morning on the Hatfield Car Park Project and was a huge success. Present were Nigel (Harper, Malling Mgr), Stuart (Project Mgr for Malling), the site construction manager, the commercial manager, the head of engineering, the engineer doing the design (it’s a design construct project for O’Rourke), the head of detailing, and me. A rough programme was produced on the board from notes on yellow stickies. Many issues were identified, decisions made, and actions agreed. At the end of the meeting, Stuart reviewed the Malling Make Ready Process and explained the expectation that the site provide call offs 7 days in advance of needed delivery. Everyone seemed very pleased to be informed and all agreed that such kickoff meetings should become standard practice. Stuart did a terrific job managing the meeting and keeping to the agenda.” (Ballard 2001).

MANUFACTURING

The transition to manufacturing occurred through the workable backlog of ‘ready work’; i.e., precast elements fully ready to be manufactured. Assignments were made to shop production teams, drawn from workable backlog in response to project call offs.

ASSIGNMENT PROCESS

For four consecutive weeks, the Last Planner (Ballard 2000) report had shown the Finsbury Square crew failing to meet its ‘commitments’ of 1 large and 3 small stones (precast elements) per day. The reason provided was always the same: “Insufficient resources.” Investigation revealed that the ‘last planner’ was not in fact making commitments, but rather the production controller was imposing the same assignment week after week, without acting on the stated reason. Successful intervention illustrated the importance of getting genuine commitment from last planners (front line supervisors) and the importance of acting on reasons for plan failure.

“There can quite obviously be tensions between what a cell leader thinks can be accomplished, what is needed by a customer, and what must be produced with allocated resources in order to make a profit. Instance: 2001 Finsbury Square-Paul Smith (name disguised) is cell leader. Paul says he can’t cast 1 large and 3 small each day, tho’ that is what the project needs and doing so would still incur a loss of approximately 400 pounds per day. I looked at the operation with Dave and Nigel. Only one person, Alan, is trying to place all three small stones, sometimes has to wait for the crane, and is being forced to batch pouring concrete because he needs the ‘white stuff’ and that’s only batched once a day. Dave suggested putting the small ones with Wayne. That would reduce the hook availability problem, reduce congestion in the Top Shop, and possibly give Alan some help when he needs it. Good idea! I suggested making three pours of the ‘white stuff’ a day (small mixer, but batch plant guys don’t like cleaning it out). Need to establish a rhythm of fixing a cage and making all other preparations each 3 hour chunk, placing a cage in each 3 hour chunk, pouring concrete as soon as the mould is ready, and striking a mould each 3 hour chunk. That would yield the 3 stones per day needed. I think Malling receives about 100 pounds for each small stone. The 6 placer crew plus some steel fixer time costs about 1000 pounds per day, so the labour cost for the small ones should be quite a bit less than the 300 pounds revenue generated.” (Ballard 2001).

Structuring production cells

In February, 2001, experiments were performed in two production cells, Shear Walls and Nap T’s, to demonstrate the feasibility and benefits of lean production concepts, including one piece flow and pull. Production had previously been organized around functional departments: supply, welding, reinforcement steel cutting and bending, concrete, etc. Schedules were used to ‘push’ work through the various process steps required to manufacture and deliver a precast element. In deterministic systems with no variation in duration, quality, or sequence, scheduling can be effective. However, no production system is without variation. Consequently, push mechanisms tend to build up inventories between process steps as synchronization fails. Work-in-process inventories were very evident at Malling prior to its lean transformation.

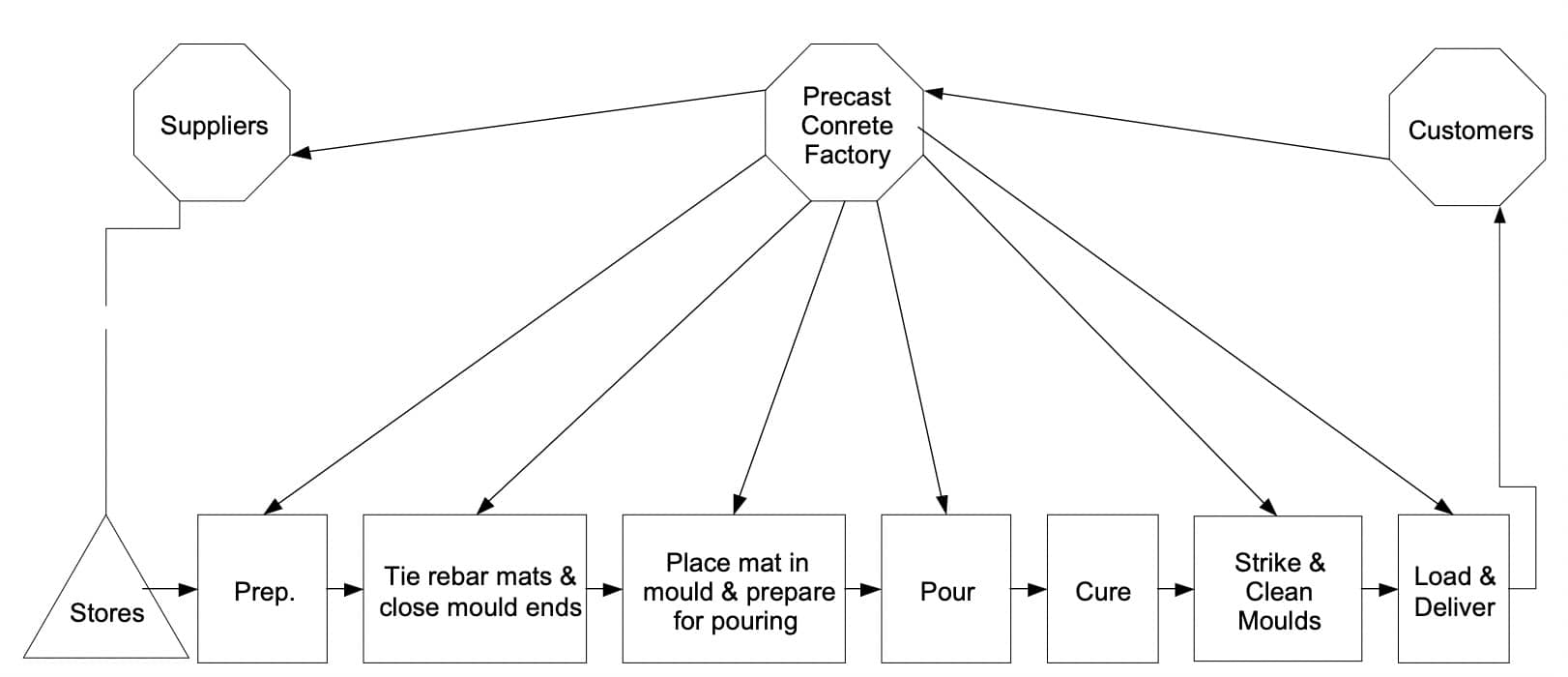

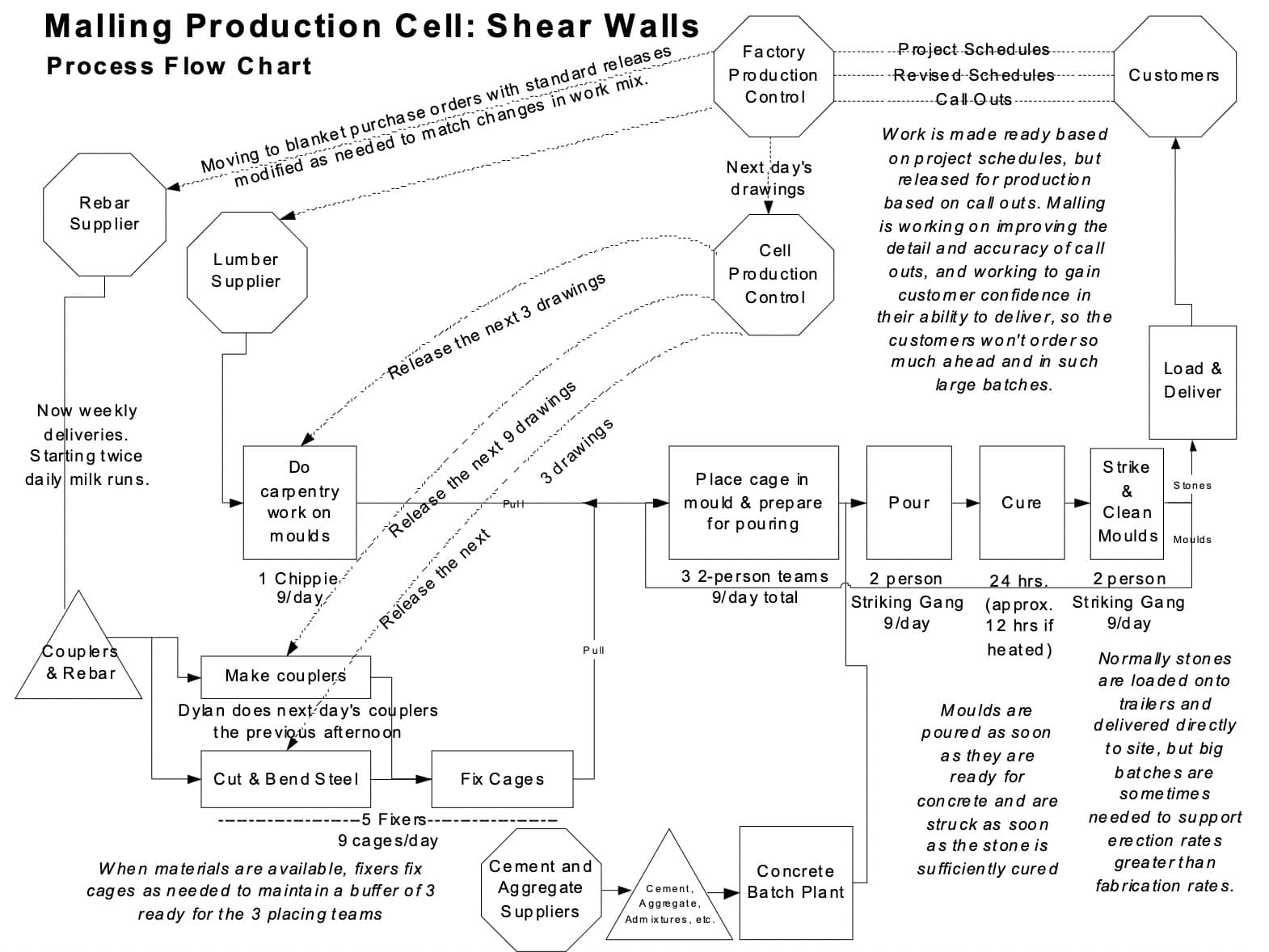

A process flow chart7 for the Shear Walls production cell, shown in Figure 6, reveals the new flow oriented design of that production system, which then served as a model for other cells. Redesign began by structuring for that output rate demanded by the client project, which needed to have 9 shear walls delivered each day for an extended period. Three two-person teams placed rebar mats in moulds. Steelfixers (reinforcing ironworkers) kept 3 mats tied and ready for placement. When a mat was taken, they tied another. This pull mechanism8 prevented build up of work-in-process inventory, keeping cycle times low and increasing cell robustness and flexibility. Once ready for concrete, moulds were filled immediately, as opposed to the previous practice of batching pours late in the day. The new system produced three shear walls in every three hour period because 3 individual walls proceeded through each of the process steps in each of those three hour periods. Further, work flow was controlled locally, by the workers in the cell, each of whom learned to ‘see’ how the entire system was performing.

LEAD TIME REDUCTION

Application of the Last Planner system of production control on projects has been demonstrated to increase plan reliability (Ballard 2000), which is measured by Percent Plan Complete (PPC): the percentage of weekly or daily releases of work from ‘supplier’ to ‘customer’ compared to what was planned. How far in advance releases (work flow) can be accurately predicted from plans establishes a window of reliability within which the supplier’s production can function effectively. With regard to engineered-to-order products such as precast concrete, it is important that lead times, the advance notice of need for delivery provided by a construction site, fall within that window of reliability. For example, suppose a construction site achieves 80% PPC (percent plan complete) looking one week ahead, but the precast supplier’s lead time is two weeks. PPC two weeks in advance might only be 60%, assuring that perhaps 40% of requested precast elements will not be able to be installed, thus building up unneeded inventory at site. If lead times do not fall within the window of reliability of the ‘customer’ process, then pulling materials from suppliers will inevitably build up unneeded inventory. On the other hand, if pull mechanisms can be used effectively, site inventories can be reduced and the production system’s robustness vastly increased.9 A shorter lead time increases system robustness because it allows less wasteful and more rapid recovery from upsets. In other words, if something goes wrong, it can be fixed quickly with minimal disruption to factory operations and to other orders.

RESULTS ACHIEVED

-

Lead times were reduced for structural precast elements to 1 week (call offs 1 calendar week ahead of needed delivery), corresponding to a reduction in manufacturing cycle time10 to 1-1/3 days:

-

The Shear Wall production cell had previously averaged 3.2 walls per day, with 12 workers. After application of lean ‘rules and tools’ to restructure work flow, 12 workers produced 9 walls per day, an increase in productivity of 181%.

-

The T’s production cell was restructured in a very similar way, resulting in an improvement from a baseline of 9 T’s per day to 18 T’s per day, an increase in productivity of 100%.

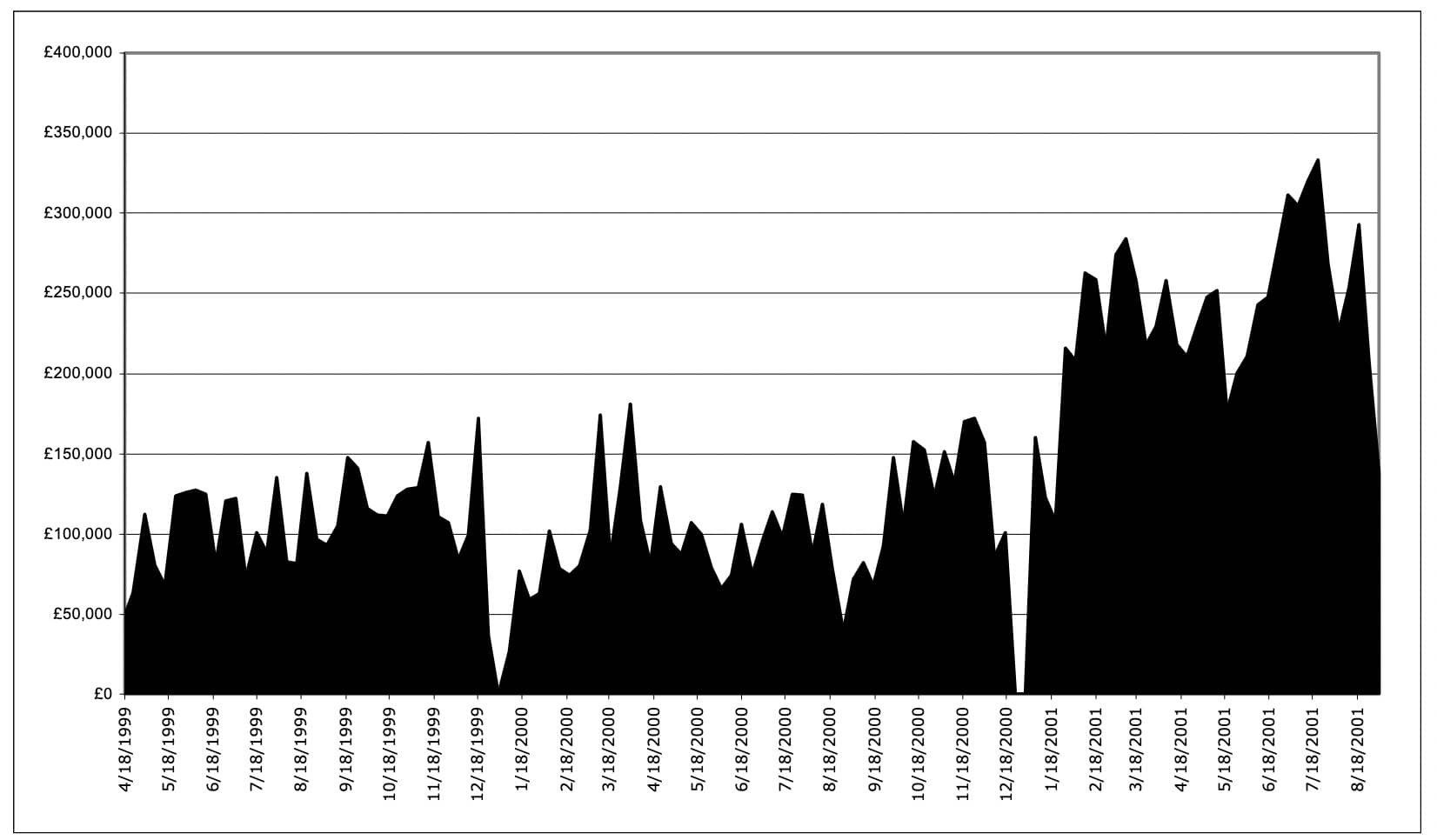

One piece flow and pull concepts were rapidly extended to other production cells. In consequence, factory throughput as measured by revenue, shown in Figure 7, changed from an average weekly rate of 130,000 pounds sterling prior to February, 2001 to an average weekly rate of approximately 260,000 pounds sterling afterwards, with an increase in work force from 115 to 122. Reports from the 1st quarter of 2002 indicate that revenue has restabilized at approximately 300,000 pounds sterling per week.

A number of actions and changes signaled a shift in management philosophy toward employee involvement and empowerment; specifically: a) formation of the Quality of Work Life Council and immediate action on its first recommendations, b) involvement of factory personnel in design and implementation of process improvements, and c) making direct workers responsible for controlling work flow within their production cells.

Production system robustness was increased in direct consequence of reducing cycle time.

CONCLUSIONS

The results achieved at Malling illustrate the power of lean concepts and techniques and their applicability to the operations of fabricators supplying engineered-to-order products to construction projects. Of special note is the fact that substantial improvements in performance were achieved with little capital investment and without changing technology or how specific operations were performed. No new machinery was engaged. Reinforcing steel was cut and bent just as before. Cages were tied and placed in moulds just as before. Concrete was mixed and placed just as before. The change was rather made in management philosophy and in work structure. Management shifted its focus from resource utilization to work flow, seeking to maximize value and minimize waste. Production was restructured for flow and pull to customer demand.

As for future research, some specific issues may require clarification; e.g., 1) limitations of the decoupling buffer strategy for managing demand variability, and 2) what fabrication processes can be structured as line flows. However, the primary challenge for future research is to extend lean concepts and techniques to other types of engineered-to-order products and to other fabricators of precast concrete, in an effort to develop a general theory and guide to practice suitable for all types of engineered-to-order products.

ACKNOWLEDGEMENTS

This case study would not have been possible without the generous support and participation of O’Rourke Ltd., Malling Precast Products, Strategic Project Solutions, and BAA.

FOOTNOTES

Glenn Ballard is Research Director for the Center for Innovation in Project and Production Management (dba Lean Construction Institute) and Adjunct Associate Professor at the University of California at Berkeley, ballard@leanconstruction.org.

Nigel Harper is Operations Director for Malling Precast Products Ltd., a wholly owned subsidiary of O’Rourke Ltd., nharper@orourke.co.uk.

Todd Zabelle is President of Strategic Project Solutions, tzabelle@strategicprojectsolutions.net

To “decouple” is to make one activity independent of another. See Slack (1997) on inventory buffers.

See Ballard, et al. (2001) and Koskela (2000) for more on production system design and goals.

The ultimate intent is to use a 3D model to do prototyping prior to producing a physical mockup.

The flow chart is modeled after Toyota’s materials and information flow diagrams. For details, see Rother and Shook (1998), who use the term “value stream maps”.

For more on pull, see Hopp and Spearman (2000).

A production system is said to be more robust if it can function effectively under a wider range of conditions and is less vulnerable to upset or disruption (Taguchi et al. 2000).

Manufacturing cycle time is the time it takes for a product to be transformed from raw material to finished product. In this case, the starting point is release of an element to the factory for production. Lead time is that amount of time in advance of delivery that “orders” must be sent to the supplier.

REFERENCES

Ballard, G. (2000). The Last Planner System of Production Control. PhD thesis, Dept. of Civil Eng., U. of Birmingham, U.K., 198 pp.

Ballard, G. (2001). “Case Study in Precast Concrete Fabrication: Malling Precast Products” Technical Report 2001-1, Lean Construction Institute, Ketchum, Idaho.

Ballard, G., Koskela, L., Howell, G., and Zabelle, T. (2001). “Production System Design in Construction.” Proceedings of the 9th annual conference of the International Group for Lean Construction, Singapore, 15 pp.

Hopp, W.J. and Spearman, M.L. (2000). Factory Physics: Foundations of Manufacturing Management, 2nd edition. McGraw-Hill International Editions, Management & Organization Series, New York, NY, 698 pp.

Howell, Gregory and Glenn Ballard (1995). Managing Uncertainty in the Piping Function. Construction Industry Institute, University of Texas, Austin, TX., November, 1995.

Howell, G. and Ballard, G. (1999). Design of Construction Operations. Lean Construction Institute White Paper 4, Ketchum, Idaho, 9 pp. Available at www.leanconstruction.org

Johnson, H.T. and Bröms, A. (2000). Profit Beyond Measure. The Free Press, New York, NY. 256 pp.

Koskela, L. (2000). An Exploration towards a Production Theory and its Application to Construction. PhD dissertation, Helsinki University of Technology, Helsinki, 296 pp.

Rother, M. and Shook, J. (1998). Learning to See: Value Stream Mapping to Add Value and Eliminate Muda. V. 1.1, October, The Lean Enterprise Institute, Brookline, MA.

Slack, Nigel (1997). Encyclopedic Dictionary of Production Management. Blackwell Business, Oxford, U.K. 256 p.

Taguchi, G, Chowdhury, S., and Taguchi, S. (2000). Robust Engineering. McGraw-Hill, New York, NY, 241 pp.

Womack, J.P. and Jones, D.T. (1996). Lean Thinking: Banish Waste and Create Wealth in Your Corporation. Simon and Schuster, New York, NY, 350 pp.

Wortmann, J.C., Muntslag, D.R., and Timmermans, P.J.M. (1997). Customer-Driven Manufacturing. Chapman & Hall, London, UK. 464 pp.